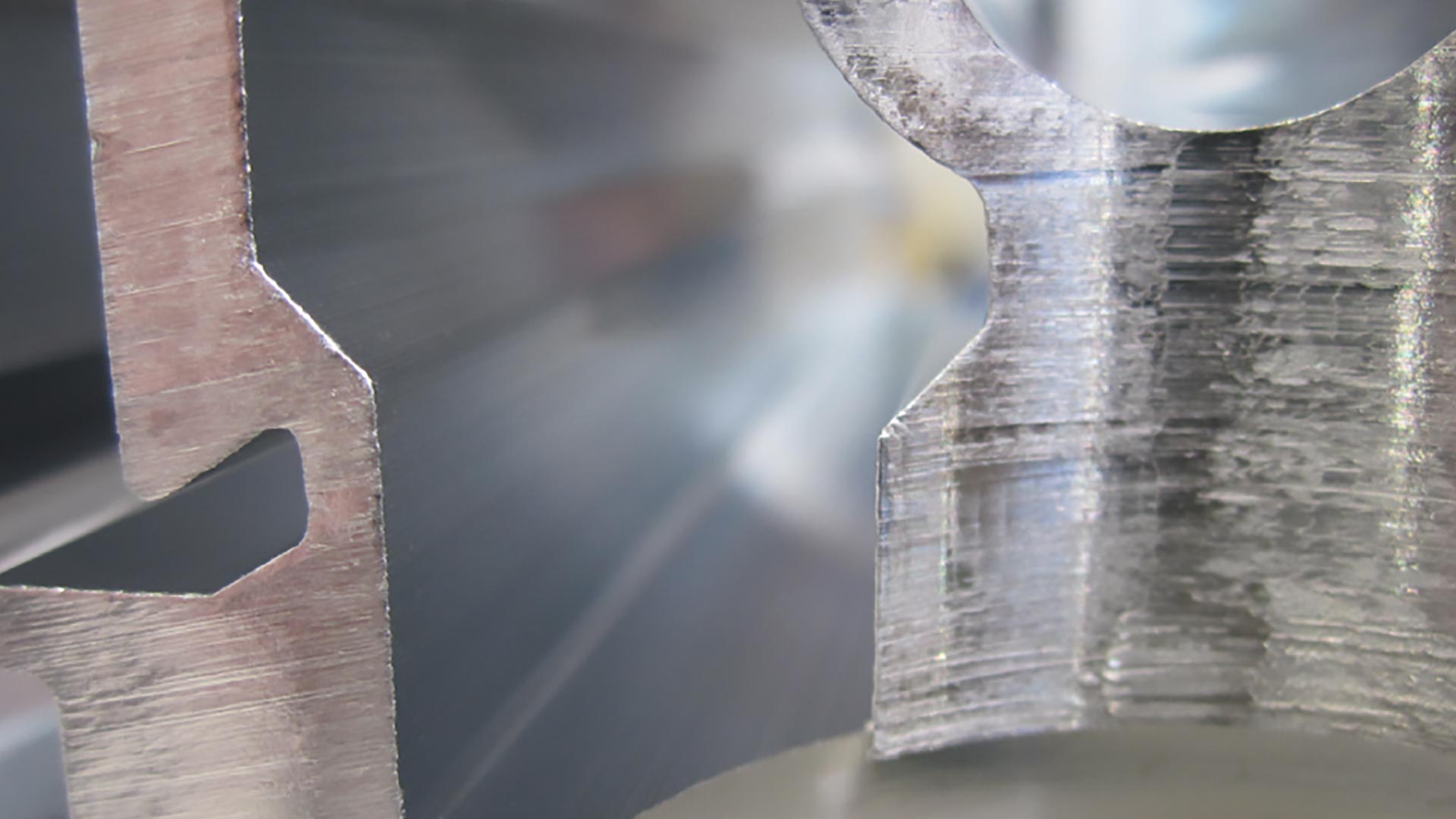

Dry ice deburring and surface treatment

Versatile and forward-looking

The standards of quality expected by many manufacturers are growing continuously alongside their innovative developments. Today, dry ice blasting systems and techniques are finding versatile applications in sectors as diverse as microtechnology and medical devices.

The requirements for surfaces are therefore very high: they must be clean, dry and deburred so that further processing, finishing or coating of workpieces can be carried out smoothly in just-in-time production.

The material properties play a subordinate role. Non-ferrous metals and plastics are the materials most suitable for dry ice blasting and deburring with dry ice.

A positive trend towards the application of dry ice blasting technology can be clearly seen in the market. Whereas the idea of cleaning with dry ice was sneered at by the market leaders in the automotive industry, even in the recent past, it has now become an indispensable – indeed imperative – component of any modern production system.

When a plastic component loses its shape, burr removal is usually a laborious business. Mechanical removal frequently also involves soiling the surface, which is counter-productive in terms of further processing. That’s why cleaning or deburring with dry ice is a logical solution.

Dry ice blasting takes care of both jobs at the same time in a single operation: deburring and cleaning – which is why this technology is so superior and fast.

For these tasks, we have developed the WL 5000 Robby dry ice blasting unit. With its variable parameters, it offers an extremely high level of process reliability and a wide range of applications.

The continuously variable delivery volume of dry ice pellets with a range from 30 kg/h to 150 kg/h allows for an economical removal rate even with very extreme soiling or burring.

The technical features are impressive, including for example a continuously variable blast pressure setting and a non-stick coating in the dry ice container. The WL 5000 Robby is specially designed for reliable, automated and continuous 24-hour use in demanding conditions.

Services in surface treatment

In many cases, the application, need or number of parts to be treated is too small to invest in a fully automated process. In such cases, we can offer you the following services:

- Deburring

- Generation of surface roughness in plastic materials

- Surface cleaning

An extensive consultation and testing with our dry ice blasting technology form the basis for our cost estimates and give you confidence in the planning and implementation of the order.

Good to know…

To incorporate the requirements and challenges of the industry into the production of these systems, you have to really understand them. For White Lion, the fact that we do is one of the main reasons we offer services of this kind.

Uncompromising alternative: the WL 5000 Robby Plus

Two in One – the dry ice blasting device with the plus: White Lion WL 5000 Robby Plus can blast as well as produce dry ice.

One of the most important conditions for the treatment is the CO2 supply for the production of the required blasting medium dry ice. Normally it is used in the form of dry ice pellets with a diameter of 3 mm and a hardness of 2 Mohs. The standard dry ice pellets cover a majority of possible use cases.

In special use cases White Lion can produce pellets with exactly specified size and volume. The application of specially designed so called scrambler nozzles enables a wide range of pellet size.

For this reason a 100% satisfying solution of your task is possible. Together with our customers we develop the dry ice blasting procedure a step further every time.

Additionally the dry ice blasting machine WL Robby Plus can produce the needed amount of dry ice autonomously and exactly. Thus the manual supply of the reservoir is no longer necessary. Sensors detect the filling level. The dry ice gets produced in an integrated unit and is then transported directly into the dosing unit.

This totally automated process is very safe to operate and comfortable in terms of control. This takes the load off your staff, so that it can attend to its main tasks.

Our partner companies are worldwide leading vendors of technical gases and therefore reliable partner for a trouble-free raw material supply

The highlights of the dry ice blasting machine WL 5000 Robby Plus:- Produces its own blasting medium (dry ice pellets)

- The dry ice delivery volume can be adjusted steplessly: 20 – 140 kg/h

- High quality material components, stainless steel / anodized aluminium

- Special coatings, no adhesion of the dry ice pellets

- Dry ice pellets of highest quality

- Very good material flow as no pellets clump due to humidity

- robot communication interface as desired by the customer

- Up to date, modern machine technology and process engineering

No automation without raw materials

One of the most important criteria in the treatment process is the CO2-Versorgung. supply. Our partner company is one of the world’s leading suppliers of industrial gases and therefore a reliable partner for a smooth supply of raw materials.

In industrial production, carbon dioxide is recovered from waste products generated during the production of ammonia and fertilisers. It is “captured”, purged and compressed in several stages. Liquid carbon dioxide is stored and transported under pressure and at low temperatures in tanks.

To find the optimum supply solutions for different applications, you need experience. This experience is what our application engineers bring to the table when they analyse our customers’ specific needs and work out solutions that are precisely tailored to the manufacturing process in question, thereby ensuring process reliability.