White Lion | Dry ice blasting machine | Dry ice machine | WL Antarctica XL

The “White Lion Antarctica XL” machine is a press for the production of dry ice pellets. The pellet size can be varied between 3, 10 and 16 mm by changing the die.

Dry ice machine

The production capacity of the “White Lion Antarctica XL” machine is approx. 240 kg/h with pellets of 3 mm in size.

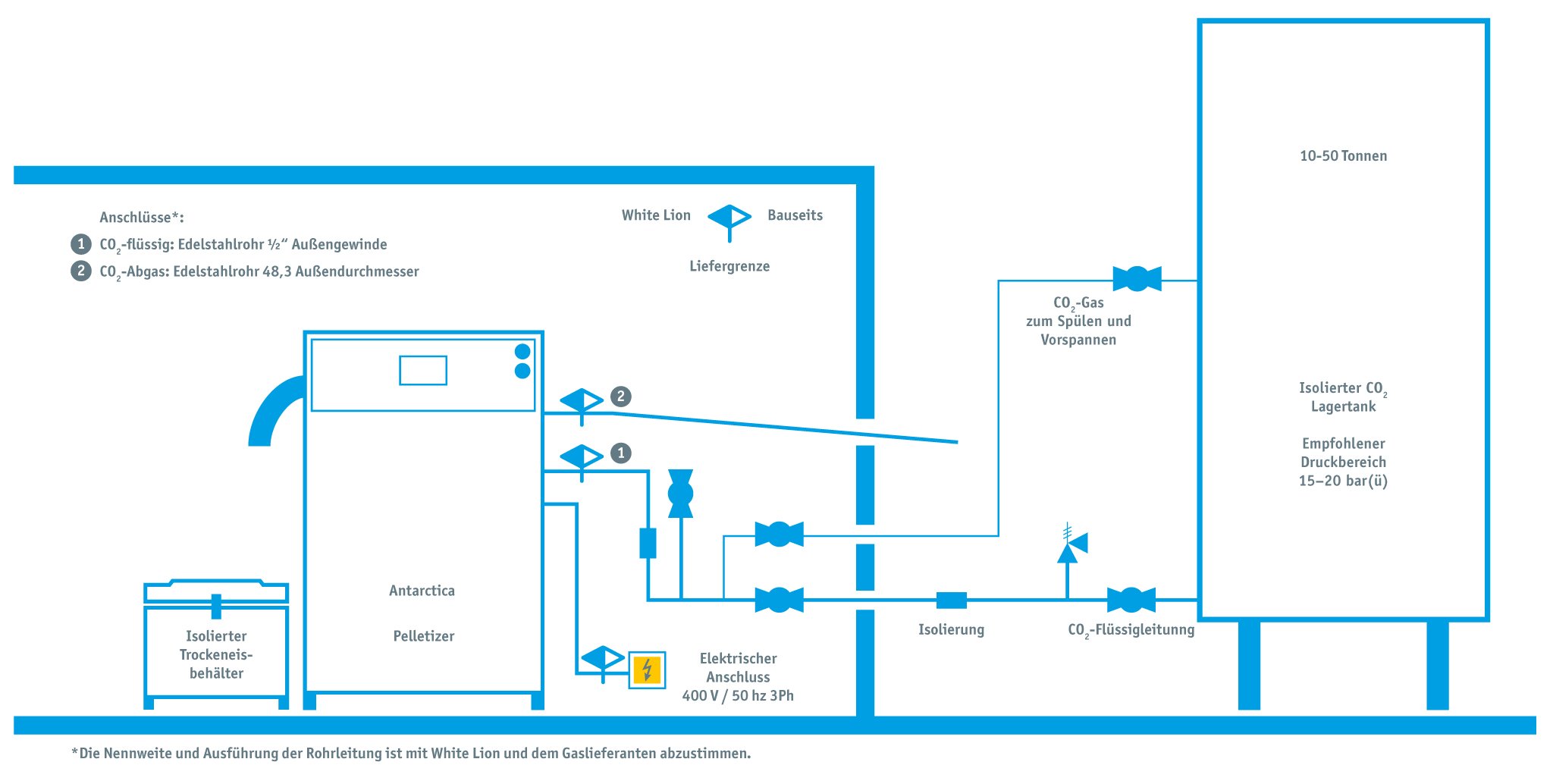

In practice, dry ice is produced by expanding liquefied CO 2from a pressure of approx. 17 bar down to atmospheric pressure from a suitable tank.

Carbon dioxide snow is produced during the expansion of the CO 2(during the transition from the tank to the atmosphere). The CO 2 is then expanded using nozzles in a press chamber. This process produces the carbon dioxide snow. In a further processing step, this is compressed with a press cylinder according to the snowball principle at a pressure of approx. 150 – 170 bar; the compressed snow is then called dry ice.

During the production of dry ice, a CO2 exhaust gas is produced during compression. If necessary, this can be liquefied again with the CO2 recovery system and fed back into production. This significantly reduces raw material consumption. Please contact us personally regarding such a system.

The commercially available dry ice molds are pellets, nuggets, slices and blocks. They are produced in so-called pelletizers, block presses or in a converter. Pellets and nuggets are produced by pressing the dry ice through a die; depending on the type and size of the die, the pellets or nuggets are produced.

Dry ice blocks are produced in so-called block presses and are simply ejected as a block or slice after the carbon dioxide snow has been compacted.

However, there is another way to produce blocks or slices: this is done by pressing dry ice pellets into slices and blocks in so-called forming machines. The great advantage of this approach is that the actual production of dry ice, i.e. the expansion and compression of C02, can be dispensed with in the so-called forming process. This saves an enormous amount of time and therefore increases the productivity of a forming machine.

Dry ice constantly sublimates, i.e. it changes from a solid to a gaseous state. An increase in volume by a factor of approx. 700 m3 can be expected. This means that 1 m3 of dry ice 700 m3 of gaseous carbon dioxide.

CO2 is oxygen-altering, has a suffocating effect and can be fatal. For this reason, CO2 production must be monitored with CO2 sensors. Excess CO2 is removed from the building with the help of fans.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information