A dry ice blasting system is an effective tool for cleaning and removing various types of soiling from different surfaces. White Lion is a manufacturer and supplier of high-quality and efficient devices that have been specially developed for blasting with dry ice.

These systems work with dry ice, which is shot onto the surfaces to be cleaned in order to remove dirt, grease or other organic substances. By using dry ice pellets as the blasting medium, the system provides a gentle and environmentally friendly cleaning solution.

The dry ice blasting systems from White Lion impress with their high performance, reliability and user-friendliness. They are available in various sizes and designs to meet the requirements of different applications.

The dry ice blasting systems from White Lion offer numerous advantages: fast and efficient cleaning, no dust formation, no chemical residues and environmental friendliness. This method is ideal for cleaning machines, facades, vehicles and other surfaces in various industries such as automotive, food, construction, aviation and more.

Dry ice blasting offers a number of advantages for cleaning surfaces.

Dry ice is an environmentally friendly blasting medium as it is non-toxic and residue-free. No chemical residues or waste are produced when cleaning with dry ice.

The sublimating effect of the dry ice on contact with the surface to be cleaned enables gentle treatment without causing damage.

With a dry ice blasting system, various contaminants such as grease, oil, paint, rust, adhesives and more can be effectively removed without the use of chemical cleaning agents or solvents.

The dry ice blast efficiently dissolves and removes stubborn dirt, enabling fast and effective cleaning.

You can reach us during our office hours (08:00 to 16:00) by telephone on 0 61 51 / 60 66 82 0

100% availability is our service concept and high availability and reliability of your dry ice blasting system is the result.

Dry ice blasting is used in various industries to thoroughly remove lubricants, paint, rust and other soiling from machines, systems, conveyor belts, tools and other machine equipment.

The use of dry ice as a blasting agent proves to be extremely effective, especially for vehicles such as cars, trucks, boats and airplanes. Paint, adhesives, seals and other contaminants can be easily removed. The dry ice blasting system is also suitable for cleaning facades, monuments, bridges, buildings and other structures. Graffiti, dirt, traces of weathering and deposits are effectively removed.

In food production, dry ice blasting is used on production lines, tanks, containers, ovens and other appliances. It safely and effectively removes food residues, grease, oil and other contaminants. The dry ice blasting system is also frequently used to restore historical buildings, works of art, furniture and artifacts. It cleans gently without causing damage.

These examples illustrate the versatility and effectiveness of this process for removing a wide variety of contaminants from different materials in many industries.

Dry ice blasting with the mobile WL 3000 professional blasting machine from White Lion is an effective method for removing stubborn dirt, paint, rust and other contaminants. The process uses dry ice pellets that are blasted onto the surface to be cleaned with compressed air at -78.9°C. The dry ice sublimates on impact with the surface, enabling fast and gentle treatment.

The WL 3000 is a very powerful dry ice blasting machine that has been developed for professional use. With a working pressure of up to 16 bar (adjustable from 1-16 bar) and a dry ice throughput of up to 180 kg/h of pellets, the WL 3000 Profi can remove even stubborn dirt effectively and efficiently. In addition, the device is easy to operate and offers a high level of reliability for use in a wide range of industries. The selection of suitable accessories (blasting gun, nozzles) enables precise cleaning on various materials.

With the mobile dry ice blasting system and a mobile construction site compressor, our customers can carry out cleaning work flexibly and efficiently. Blasting pressure and compressed air (compressor) play an important role in dry ice blasting. The blasting pressure, measured in bar, determines the intensity and efficiency of the blasting process. A higher blasting pressure removes stubborn dirt much more effectively. We recommend compressed air of at least 6 bar / 6 m3/min in order to be able to carry out the process optimally in the required pressure range (1 to 16 bar).

The professional blasting system WL 3000 from White Lion offers an environmentally friendly and cost-effective method with high efficiency and quality cleaning results. For further information on technical data and to create an individual offer, we as the manufacturer of these systems are your competent contact and look forward to working with you personally to offer an optimal overall package for your requirements.

Nozzles for dry ice blasting are specially developed nozzles that allow dry ice particles to be blasted onto the surface to be cleaned using compressed air. These nozzles are available in different designs and sizes, depending on the requirements of the application. They have been designed to enable precise and efficient cleaning without causing damage. The nozzles are robust and durable to withstand the rigors of dry ice blasting.

In dry ice blasting, choosing the right nozzle is crucial to the effectiveness and efficiency of the cleaning process. Nozzles play an important role in controlling the blast pattern, blast angle, blast speed and pressure. These factors all have a direct impact on cleaning performance.

Choosing the wrong nozzle can lead to inefficient dry ice cleaning, resulting in increased time and costs. A nozzle that is not suitable for the material or application can even cause damage to the surface, making additional repairs necessary.

One of the most important factors when choosing the right nozzle is the size and shape of the jet pattern. Depending on the cleaning task, a wide flat jet pattern may be suitable for cleaning large areas, while a concentrated round jet may be required for precise cleaning work. The nozzle should also be able to generate the correct jet pressure and speed to remove the contaminants most effectively.

Flat spray nozzles produce a wide and even jet that is ideal for use on large surfaces. They are suitable for removing dirt, paint, rust or other soiling from various materials. Round jet nozzles, on the other hand, produce a focused jet that is suitable for precise cleaning work or removing stubborn dirt from hard-to-reach areas. There are also special nozzles for specific purposes, such as nozzles with an extended tube for hard-to-reach areas or nozzles with different jet patterns for special cleaning tasks.

Choosing the right accessories is crucial for the effectiveness and efficiency of dry ice cleaning. It is important to consider the requirements of the cleaning task and select the right nozzle to achieve optimum results.

White Lion will put together an optimal offer for your purposes. Talk to us, we look forward to your inquiry!

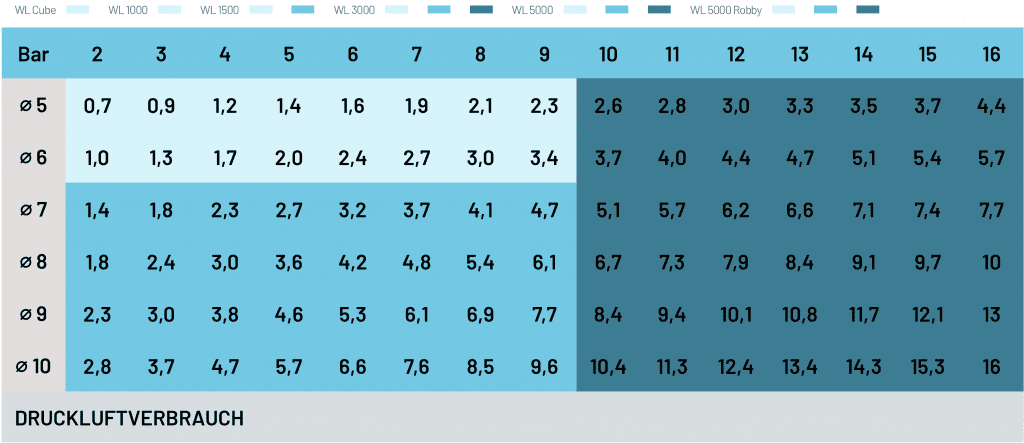

| Bar | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| ⌀ 5 | 0,7 | 0,9 | 1,2 | 1,4 | 1,6 | 1,9 | 2,1 | 2,3 | 2,6 | 2,8 | 3,0 | 3,3 | 3,5 | 3,7 | 4,4 |

| ⌀ 6 | 1,0 | 1,3 | 1,7 | 2,0 | 2,4 | 2,7 | 3,0 | 3,4 | 3,7 | 4,0 | 4,4 | 4,7 | 5,1 | 5,4 | 5,7 |

| ⌀ 7 | 1,4 | 1,8 | 2,3 | 2,7 | 3,2 | 3,7 | 4,1 | 4,7 | 5,1 | 5,7 | 6,2 | 6,6 | 7,1 | 7,4 | 7,7 |

| ⌀ 8 | 1,8 | 2,4 | 3,0 | 3,6 | 4,2 | 4,8 | 5,4 | 6,1 | 6,7 | 7,3 | 7,9 | 8,4 | 9,1 | 9,7 | 10 |

| ⌀ 9 | 2,3 | 3,0 | 3,8 | 4,6 | 5,3 | 6,1 | 6,9 | 7,7 | 8,4 | 9,4 | 10,1 | 10,8 | 11,7 | 12,1 | 13 |

| ⌀ 10 | 2,8 | 3,7 | 4,7 | 5,7 | 6,6 | 7,6 | 8,5 | 9,6 | 10,4 | 11,3 | 12,4 | 13,4 | 14,3 | 15,3 | 16 |

| DRUCKLUFTVERBRAUCH | |||||||||||||||

Compressed air consumption in m3/min. – Pressure data in bar – ⌀ = nozzle diameter 0.5 m3 (0.7 + 0.5 = 1.2 m3)

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information