White Lion | Dry ice blasting machine | Dry ice cleaning

Dry ice cleaning is a method that causes only minimal side effects compared to other blasting methods. After cleaning with dry ice, only the dissolved dirt remains, which can be easily removed. This process does not cause any damage to the surface of the cleaned material and there is no waste from used blasting material. The dry ice used turns into natural gases that are also present in the air. The result is a visibly clean surface, even with stubborn dirt.

Dry ice cleaning is a high-tech method in blasting technology that offers many advantages. It is the gentlest and most versatile cleaning method that always delivers optimum results and eliminates consequential damage. Cleaning is carried out without the use of harsh chemicals or water, at low temperatures and without finely dispersed blasting material.

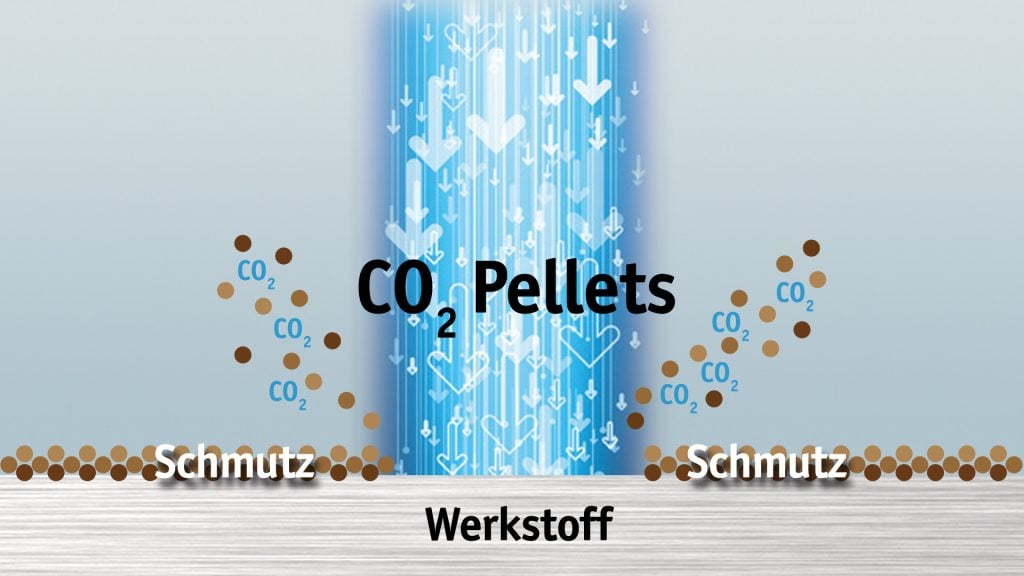

In dry ice cleaning, dry ice pellets of frozen carbon dioxide are shot onto the surface at high speed and under pressure. These pellets have a temperature of -78 °C and loosen unwanted adhesions on contact with the dirt. The subsequent evaporation of the pellets creates additional pressure, which acts like shock waves on the dirt. The extremely low temperature of the dry ice ensures that the dirt becomes brittle. As a result, this gentle cleaning method can also be used in areas where other methods fail.

In contrast to other cleaning methods, which can lead to destruction, dry ice cleaning offers a gentle way of thoroughly cleaning various materials.

Getting something clean usually requires a combination of a damp cleaning agent and mechanical force to remove stubborn dirt. Regardless of whether water or chemical cleaning agents are used, a residue remains that must be disposed of. In addition, the cleaning agent itself often poses a risk. Water can lead to mold, rust or short circuits. Chemical cleaning agents can emit harmful vapors and attack the surface to be cleaned.

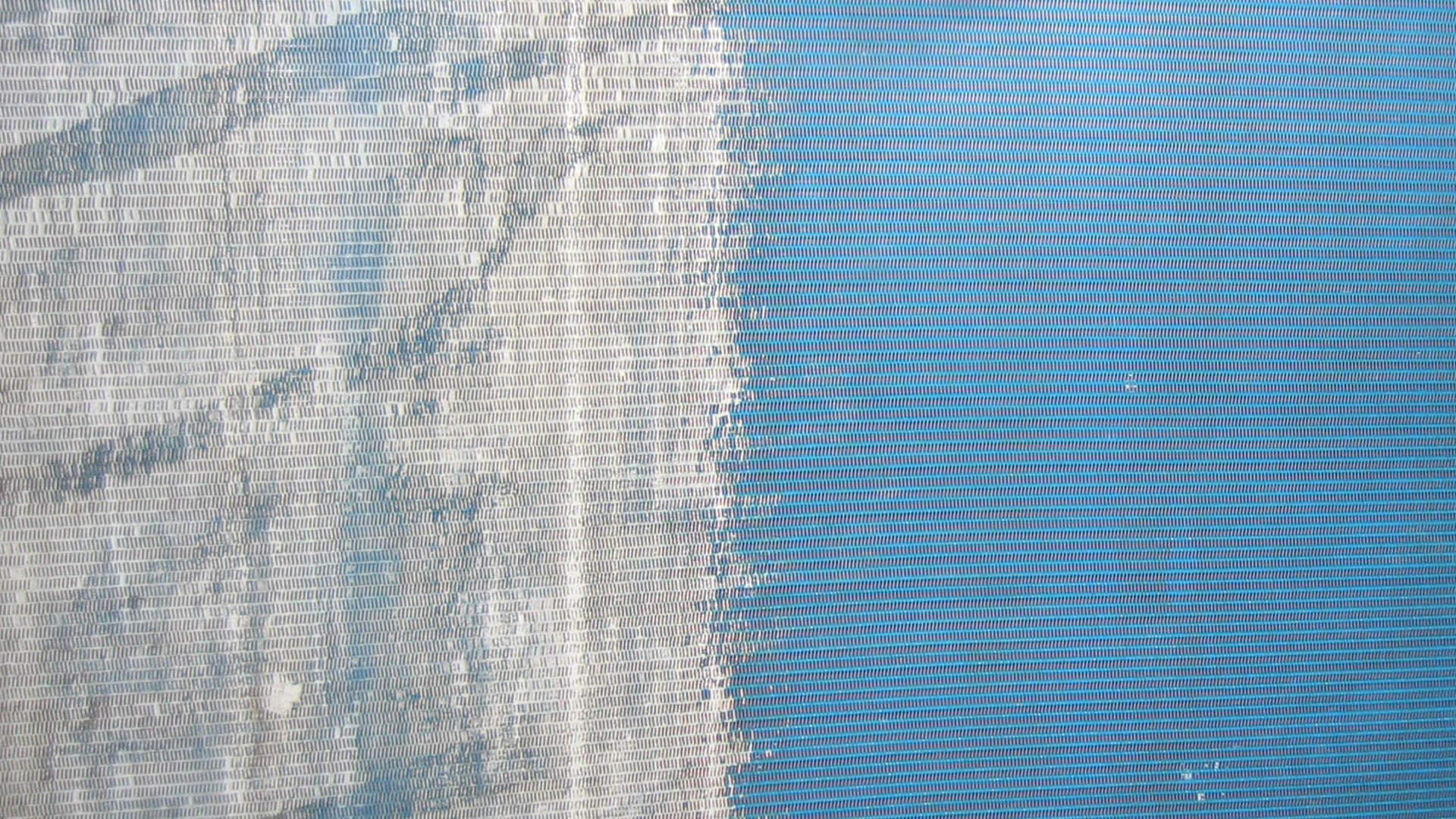

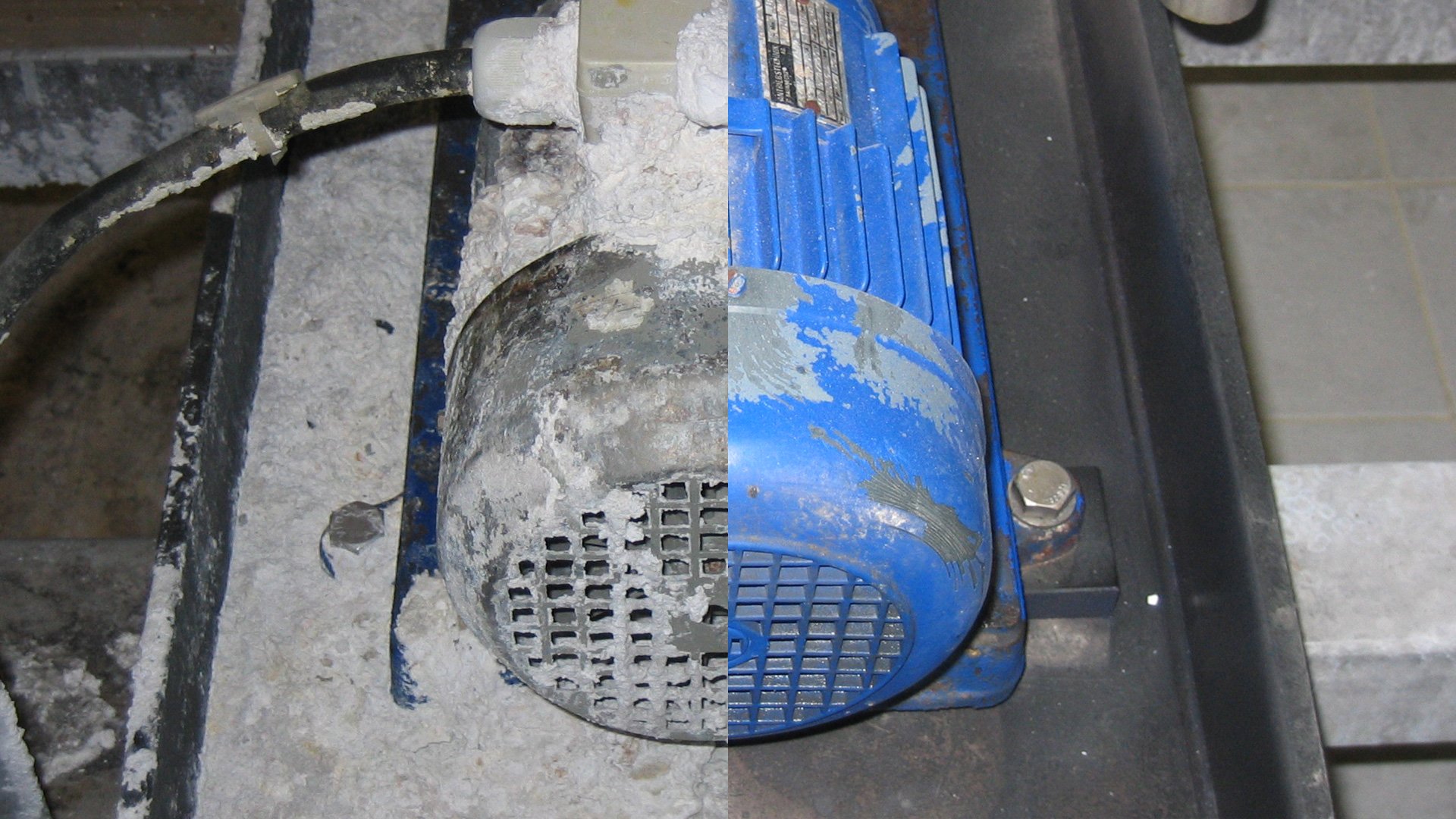

It becomes particularly challenging when the surface consists of different materials. Motors, machines, circuit boards or electrical switchgear consist of a variety of materials: Glass, plastic, metal – painted or unpainted, fiberglass, rubber and many more are arranged close together. With conventional methods, you can either only clean one part or risk damaging other components.

An impressive example of the effectiveness of dry ice blasting is cleaning the inside of a car door. This involves cleaning various surfaces such as bare sheet metal, painted surfaces, plastics, fabrics, electrical switches, deep grooves and openings. Normally, you would have to dismantle the entire door and clean each component individually to achieve a thorough clean. However, the dry ice blasting process eliminates this time-consuming process. The door remains intact and all surfaces are cleaned at the same time. Even sensitive switches can be treated without risk. Dry ice cleaning removes crumbs and stains, deep cleans switches and even refreshes leather – all in the shortest possible time. This method is not only more thorough and gentler than conventional cleaning methods, but also much faster. The entire vehicle interior can therefore be cleaned efficiently, while unpleasant odors are also removed.

The dry ice blasting process also offers a wide range of other applications in various sectors, from industry to the automotive industry and beyond. Dry ice blasting can be used to clean wood thoroughly and gently, including the removal of paint and lettering. This is particularly useful when renovating houses and cleaning wooden furniture.

This process also offers an effective and inexpensive solution for removing underbody protection, anti-fouling paint or rust from vehicles and boats. Dry ice cleaning can also be used to remove adhesives, lettering and stuck-on films quickly, cleanly and without leaving any residue.

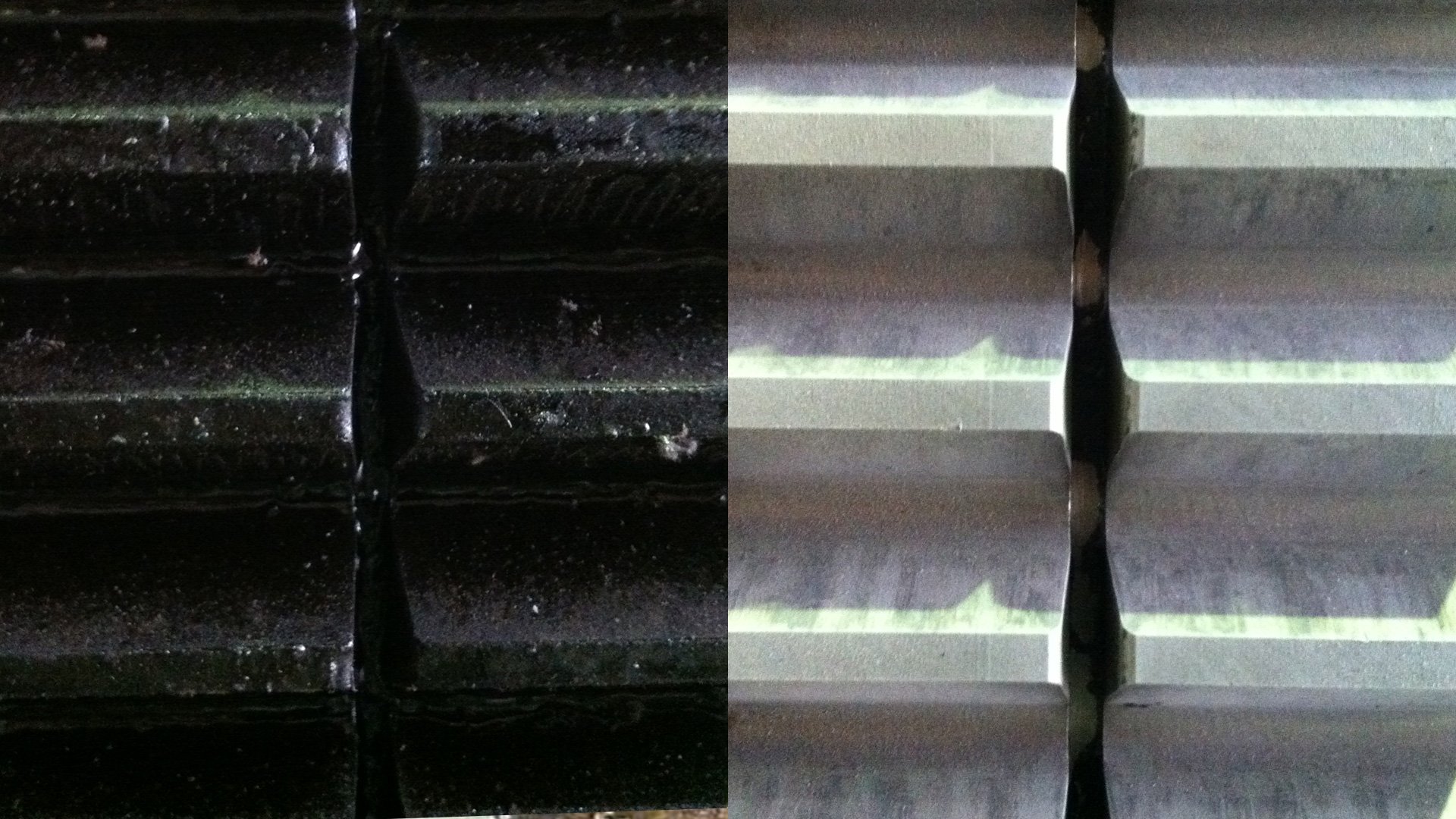

Dry ice cleaning is also used for industrial cleaning to clean tools, press molds and other equipment. It is particularly useful for removing hot glue and cleaning gear parts. Dry ice blasting can effectively clean molds in the casting industry by removing a variety of contaminants.

This cleaning process can be used to remove paint from buildings and facades and to clean clinker bricks. This is particularly useful for restoration work and cleaning historic buildings. Dry ice can be used to remove stubborn dirt from aluminum, facades and many other surfaces.

Dry ice blasting machines can also be used to clean heavily soiled motorcycles when conventional cleaning methods are not sufficient. Dry ice can be used to remove fire damage without the use of water or cleaning agents, which is particularly useful when quick and environmentally friendly cleaning is required.

These examples illustrate the versatility and efficiency of dry ice blasting in various application areas.

Compared to conventional blasting methods, the dry ice blasting process offers numerous advantages that make it an attractive option for various applications. The dry ice blasting process is efficient, gentle and environmentally friendly.

Compared to conventional processes, the dry ice blasting process is extremely efficient. The time savings are enormous, as dry ice blasting only takes a few hours, whereas conventional methods take several days or weeks.

In contrast to sandblasting, dry ice cleaning is a very gentle process. It enables sensitive surfaces such as paint, rubber and plastic to be cleaned without removing any substance. Damage caused by scraping or sandblasting does not occur with dry ice cleaning.

Dry ice cleaning is environmentally friendly and non-toxic. As dry ice does not contain any water, it does not produce any harmful vapors, as is the case with scarfing. It also causes no corrosion and leaves no problematic blasting material residues. Cost savings: Dry ice cleaning saves costs as no dismantling is required and there are no follow-up costs for painting work. Removed dirt is simply disposed of.

Dry ice is non-conductive, which means that it can also be used on electrical and electronic components without causing consequential damage. In contrast, cleaning with water can cause damage.

Dry ice cleaning offers technical advantages such as high cleaning efficiency, the avoidance of dismantling sensitive system components and the possibility of inline cleaning at operating temperature.

Dry ice cleaning reduces machine downtimes and cost-intensive repairs. In addition, cleaning intervals can be extended thanks to the high quality of the cleaning method.

These advantages make dry ice cleaning an attractive option for various applications in different industries.

Blasting nozzles are an indispensable component of dry ice blasting systems and play a decisive role in the effectiveness of the cleaning process. They transfer the dry ice to the surface to be cleaned in a jet of compressed air. Selecting the right blasting nozzle is crucial to achieving optimum results and maximizing cleaning efficiency.

There are different types of blast nozzles that are suitable for different applications. The selection of the right nozzle depends on various factors, such as the size and shape of the surface to be cleaned, the material to be cleaned and the application environment.

Important aspects when selecting blast nozzles for dry ice cleaning are the diameter of the nozzle, the material it is made of and its design. It is crucial to consider the specific requirements of the cleaning task in order to select the appropriate blasting nozzle.

For special applications, White Lion offers the option of customizing the pellets for dry ice blasting machines. You can specify the exact size and volume. By using so-called scrambler nozzles, it is possible to use different blasting media sizes for dry ice blasting. In this way, we can always meet your requirements to your complete satisfaction.

You can reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

At White Lion, we are experts in the field of dry ice blasting. With over 25 years of experience, we are one of the leading pioneers of this technology. Dry ice blasting was one of the first services we offered in our company history. Our daily work with the equipment at that time inspired us to develop our own innovations in the field of dry ice blasting. Today, our machines can easily meet even the highest requirements.

Our goal is still to achieve the best, gentlest and most sustainable results with dry ice blasting. Feel free to contact us to find out more about our expertise in dry ice blasting. Put your trust in our expertise and work with us to find the right approach for your cleaning challenges.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information