Dry ice pelletizers are specialized machines driven by a powerful hydraulic power unit that are used to produce dry ice from liquid carbon dioxide. These machines can pressurize and cool carbon dioxide to produce liquid carbon dioxide, which is then fed into a pelletizer. In the pelletizer, the pressurized carbon dioxide is expanded to atmospheric pressure, causing it to solidify into a snow-like consistency and then pressed into pellets, nuggets, blocks or slices.

The use of pelletizers is indispensable in Industry 4.0, as they offer high quality and flexibility. By using pelletizers in dry ice production, a fresh product can be produced that can be used directly for dry ice blasting machines, thus delivering optimum cleaning results.

The “White Lion Antarctica S” machine is a press for the production of dry ice pellets. The pellet size can be varied between 3, 10 and 16 mm by changing the die. The production capacity is approx. 120 kg/h with pellets of 3 mm in size.

Electric

Mechanical

With the “White Lion Antarctica XL” machine, the production capacity is approx. 240 kg/h with pellets of 3 mm in size. The pellet size can be varied between 3, 10 and 16 mm by changing the die.

Electric

Mechanical

You can reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

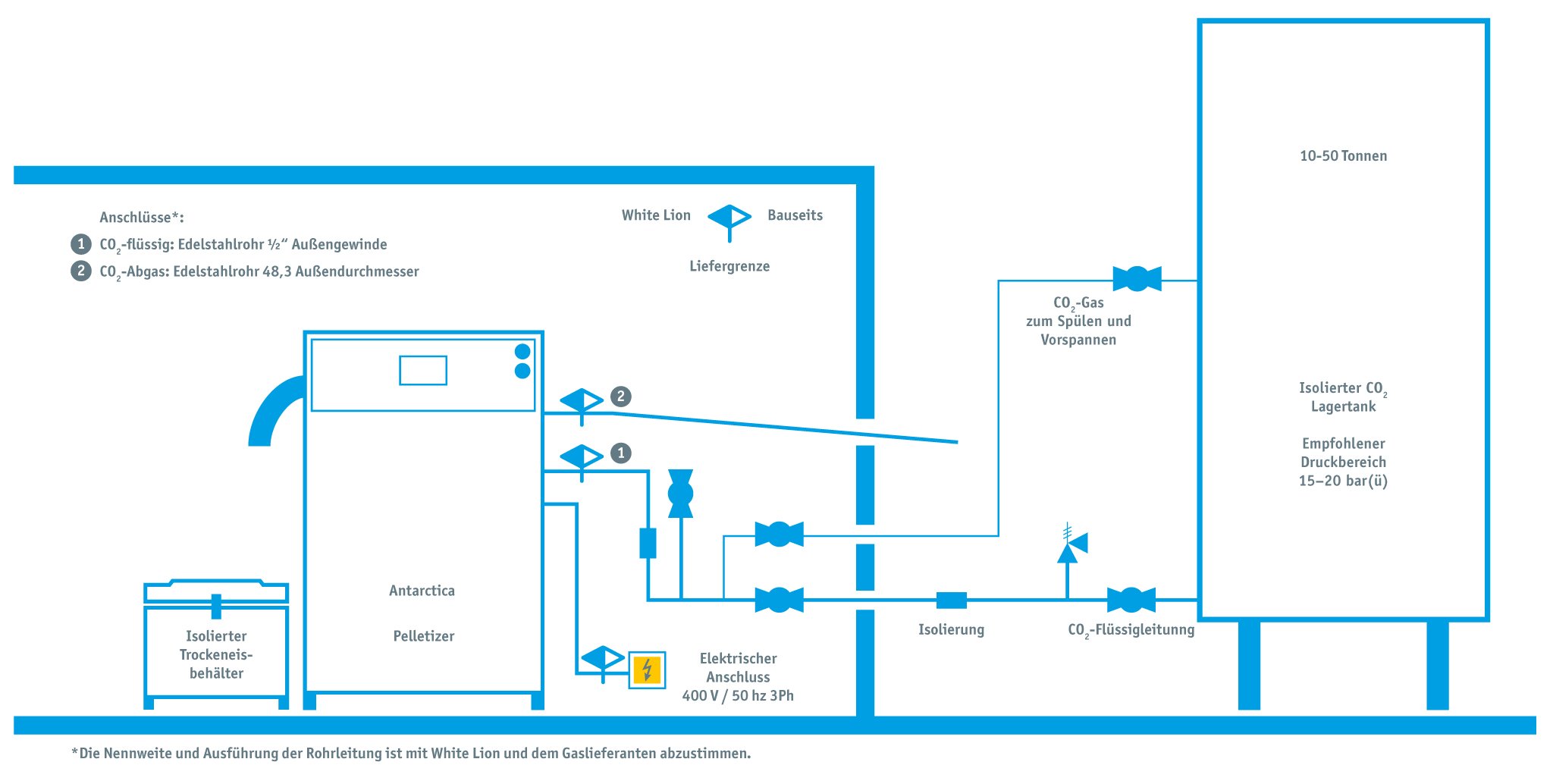

In addition to the dry ice pelletizer, dry ice production requires a CO2 source, a CO2 storage tank, a CO2 connection and various press dies and other accessories to adapt to individual requirements.

Dry ice pelletizers are ideal for a wide range of applications – for example, cooling food, pharmaceutical products or motors, deburring workpieces and cleaning sensitive surfaces. For companies with a large demand for dry ice, in-house dry ice production can be economical in the daily work process.

Equipped with different dies, different extrusion and end product sizes can be produced (pellets, nuggets, slices and blocks), allowing for a wide range of applications. Dry ice machines are particularly useful for companies looking for efficient methods to produce large quantities of high quality dry ice at low cost.

With our WL Antarctica dry ice pelletizer, we offer solutions for smooth dry ice production, from small-scale to continuous operation under demanding conditions.

Frozen CO2 is used as an abrasive to remove stubborn dirt and contaminants from various surfaces. It is particularly gentle on sensitive parts such as electronic components or fine surfaces, as it does not cause scratches or abrasion.

The application of dry ice blasting extends to various industries such as the automotive industry, mechanical engineering, food processing, the electronics industry and the restoration of historical artifacts. It is suitable for removing rust, paint, coatings and grease and oil residues from metal parts.

Due to the sublimating effect of the blasting material, it changes directly from a solid to a gaseous state and leaves no residue on the cleaned surface. This makes additional cleaning steps superfluous.

As dry ice pellets are non-abrasive and there is no physical wear, it is safe to use for electrical components. In addition, carbon dioxide is a non-toxic material with no harmful emissions during cleaning.

Frozen carbon dioxide offers an effective, precise and environmentally friendly cleaning method for a wide range of applications.

Production takes place by sublimation, in which pressurized liquid carbon dioxide is released. Part of the carbon dioxide evaporates and extracts the heat required for evaporation from the rest, causing the remainder to cool and sublimate into frozen carbonic acid snow. This process takes place by releasing liquid CO2 under pressure into the environment at a CO2 inlet pressure of approx. 17 bar. This produces gaseous vapor and solid snow. The snow is then compressed to form blocks. Pellets or nuggets are produced by compression and using extruder plates.

Dry ice is solid carbon dioxide with a temperature of -78 °C. Under atmospheric pressure, carbon dioxide sublimates directly into a gaseous state without first becoming liquid. This property means that dry ice practically disappears when heated without leaving any residue or waste. The carbon dioxide used for production is a natural by-product of various industrial processes such as fermentation and petrochemical refining. The resulting carbon dioxide is captured without loss and stored until it is used – no new CO is produced; only existing CO is released. The use of dry ice is therefore carbon-neutral and environmentally friendly.

If necessary, the CO2 waste gas produced during the manufacture of solid carbon dioxide can be liquefied again using a carbon dioxide recovery system and fed back into production.

Dry ice pellets generally have a diameter of 3 mm and are used both as a blasting medium for dry ice blasting and for cooling a wide variety of products.

Our 4mm power pellets are an absolute novelty. These are characterized by a particularly long service life and stability. When used in the blasting process, the 4mm pellets, which are 33% larger than 3mm pellets, achieve a significantly higher kinetic energy on the surface, which in turn means a higher removal rate.

We also produce nuggets with a diameter of 10, 12 and 16 mm. Nuggets are used exclusively for cooling. Possible applications include the pharmaceutical and chemical industries as well as the food industry.

Dry ice blocks have a high cooling volume and are suitable for transport refrigeration in logistics, especially for international air freight.

Blocks and disks are also used in the chemical and pharmaceutical industries.

We at White Lion will advise you in detail and help you to weigh up whether in-house dry ice production is economically advantageous for your company. If you have a higher demand for dry ice, it may make sense to produce it yourself. Costs, safety measures, availability and legal regulations must be taken into account before this decision is made. White Lion is your competent partner here. Benefit from our many years of experience in this cool industry.

We look forward to receiving your inquiry and will be happy to provide you with information on the technical data of our high-performance appliances and all their functions, from production capacity to weight.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information