White Lion | Blasting Alliance | Dry ice cleaning | Deburring | Deburring threads

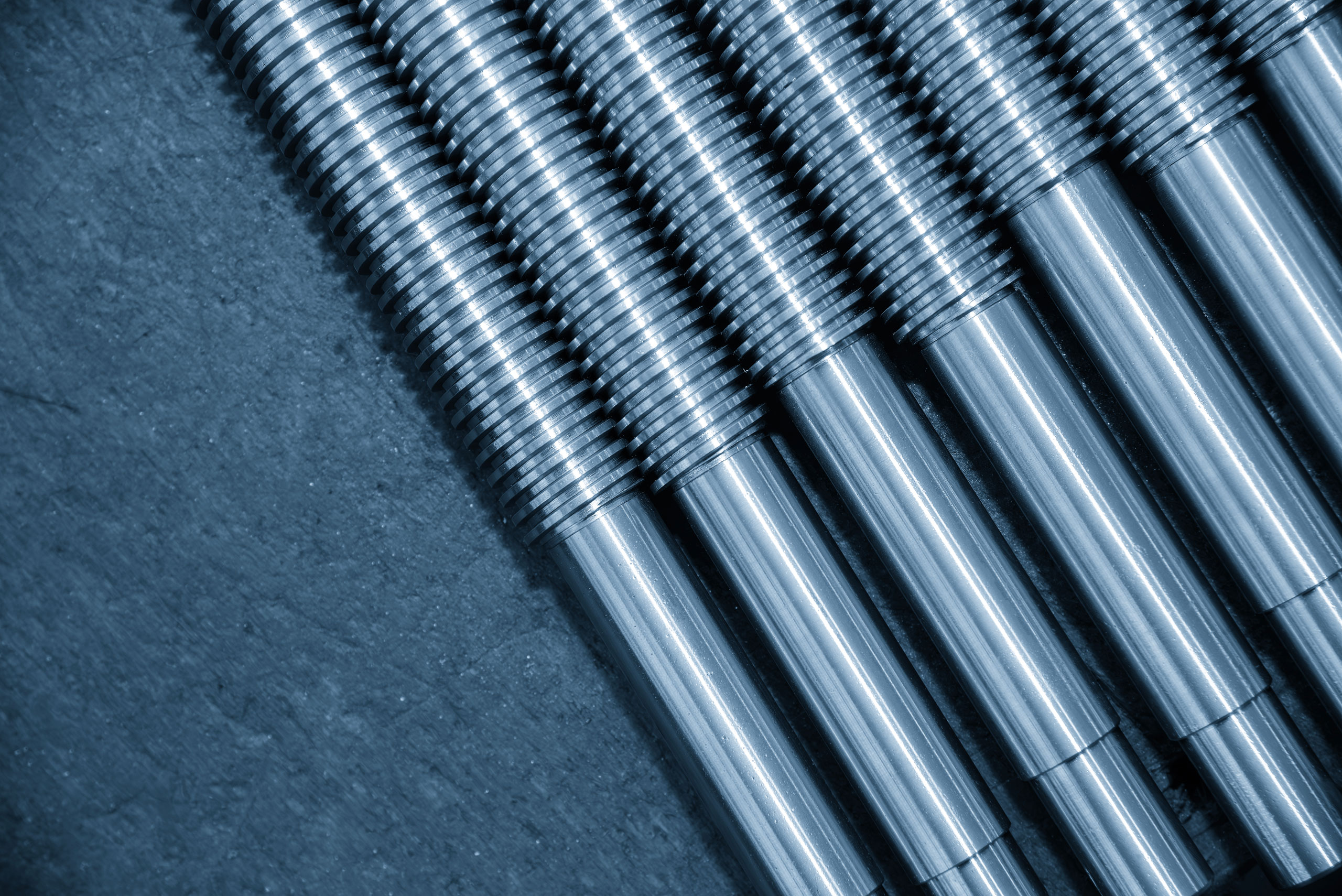

Deburring threads is a critical step in the metalworking industry that often determines the functionality and service life of components. Burrs on threads can not only make assembly more difficult, but can also impair the mechanical properties and tightness. One of the most effective and gentle methods for processing threads is deburring with dry ice. This innovative technology offers numerous advantages and has increasingly established itself as a standard process in various branches of industry.

A major advantage of dry ice blasting is the gentle treatment of sensitive materials. While many conventional deburring methods, such as grinding or milling, tend to stress or even deform the surface, dry ice blasting leaves the base material intact. This is particularly important when it comes to precision threads designed for highly stressed applications.

The integration of dry ice blasting into automated manufacturing processes opens up considerable advantages for the efficiency and cost-effectiveness of production. Dry ice blasting can be easily integrated into automated manufacturing processes, which shortens throughput times and increases productivity. Thanks to the high cleaning effect, components can be processed and prepared for assembly more quickly, leading to an overall reduction in costs.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information