White Lion | Blasting Alliance | Blasting process for industrial cleaning | Sponge Jet process

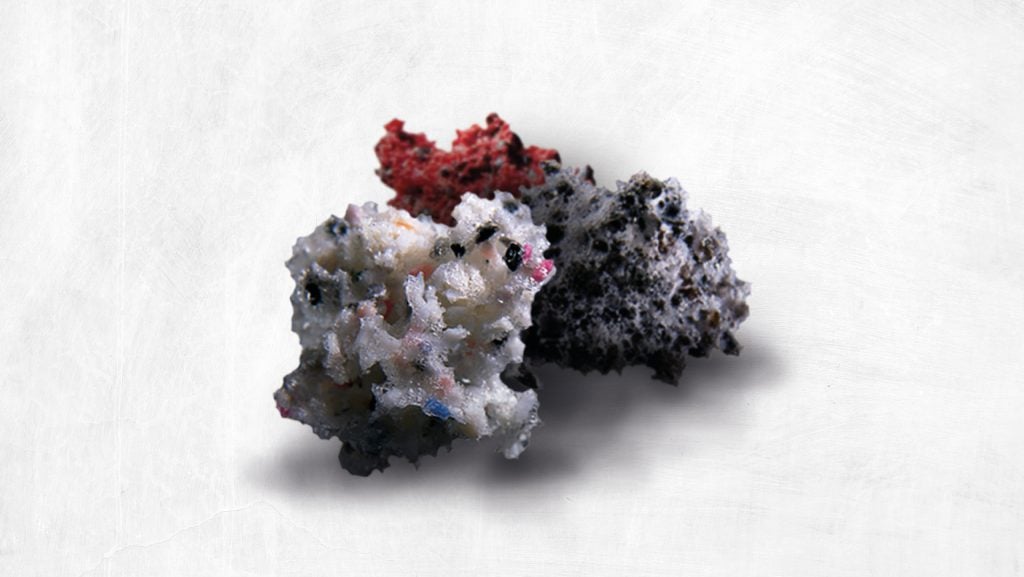

Sponge-Jet technology uses a reusable abrasive encased in a Sponge Media™ to fulfill a variety of applications, from complex shaping to gentle processing of delicate surfaces.

The Sponge Jet Media is an innovative abrasive for cleaning and preparing surfaces for coating. It reduces dust and protects the surface through gentle impact.

The machine works with a special process in which the blasting media is flattened by the impact and then absorbs dust and dirt through the expansion of the Sponge Media™. This ensures efficient and gentle blasting without impairing the corrosion protection. A mixture of water, air and fine sponge particles is blasted onto the surface under high pressure. With the combination of a gentle jet and abrasive sponge particles, stubborn dirt and coatings can be removed without damaging the surface. This makes Sponge Jet particularly suitable for cleaning sensitive surfaces of historic buildings, monuments or bridges.

Another advantage of Sponge-Jet technology is the high reduction of dust and dirt, resulting in a clean and pollutant-free surface. The Sponge Media™ cells capture up to 95% of pollutants, which significantly minimizes emissions.

In addition, Sponge-Jet offers sustainable and safe substrate preparation through recycling. The recycler uses high frequency vibrations to shake and drop the reusable sponge media in a spiral path over screens. This separates unwanted contaminants and reuses the blast media, reducing the environmental impact. Silver Sponge recyclable material achieves first-class results for any type of material. The use of recyclable blasting media such as Sponge-Jet Media not only protects the environment, but also improves corrosion protection. This technology also enables the efficient use of machines and processes that are easy to operate.

The Sponge-Jet system is easy to operate and designed for continuous operation. A pneumatically controlled screw conveyor system ensures a constant supply of the blast media in an air stream, which guarantees maximum throughput and reliable operation.

Sponge-Jet offers a range of applications from aggressive shaping to the gentle processing of coatings. With a sponge-jet system, you can work efficiently and in an environmentally friendly manner without having to compromise on quality and safety. The advantages of jet blasting lie in its gentle process, which enables effective blasting of sensitive carrier layers without damaging them. This technology is ideal for users who require an efficient and reliable solution for processing surfaces.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

The Sponge-Jet blasting process is an innovative method of surface preparation that works with Sponge Media™. The use of Sponge Media™ enables environmentally friendly and sustainable surface preparation that not only saves time, but also lowers overall costs and reduces water consumption. It has applications in various fields such as contaminant remediation, infrastructure, chemical, maintenance, petroleum natural gas, manufacturing, marine, military, energy, transportation and remediation.

Sponge Media™ produces up to 98% less dust than conventional abrasives, resulting in a cleaner and more efficient surface finish. This process offers almost unlimited visibility, reduces waste by up to 96% and hazardous dust by more than 98%, resulting in significant savings.

The simultaneous execution of blasting, cleaning and inspection using Sponge-Jet technology reduces the workload and lowers overall costs. In maritime applications in particular, the technology is used for surface preparation before coating ship roofs, stairs, cabins and pipes.

The recyclable Sponge Media™ abrasives reduce material transportation and disposal, provide dust suppression and protect sensitive equipment and the environment. The use of Sponge Media™ is therefore an efficient and environmentally friendly solution for surface treatment in various industries. With its outstanding results in terms of time savings, reliability, corrosion protection and reduction of overall costs, it offers a sustainable alternative to traditional blasting processes.

You can also reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information