White Lion | Blasting Alliance | Dry ice cleaning | Remove impurities | Remove bitumen

Bitumen is widely used in various industries, particularly in road construction and waterproofing. Its tough and sticky nature ensures that it provides a reliable bond, but this can also lead to removal challenges. Dry ice cleaning is an interesting alternative to conventional methods because it is based on physical principles that allow gentle handling of surfaces.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationA surface covered with stubborn bitumen shows an unsightly, sticky and uneven surface. The typical black color of bitumen covers the underlying structure and makes further treatment or renovation virtually impossible. The unsightly appearance also attracts dirt and debris, which detracts from the overall aesthetics.

After dry blasting, the surface appears in new splendor. The process effectively removes the bitumen without damaging the underlying surface. The surface is now clean, free of residue and ready for subsequent work, be it resurfacing, sealing or any other type of treatment. The previous condition, often accompanied by annoyance and frustration, is replaced by a clean and attractive surface that meets the requirements of modern construction and renovation techniques.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

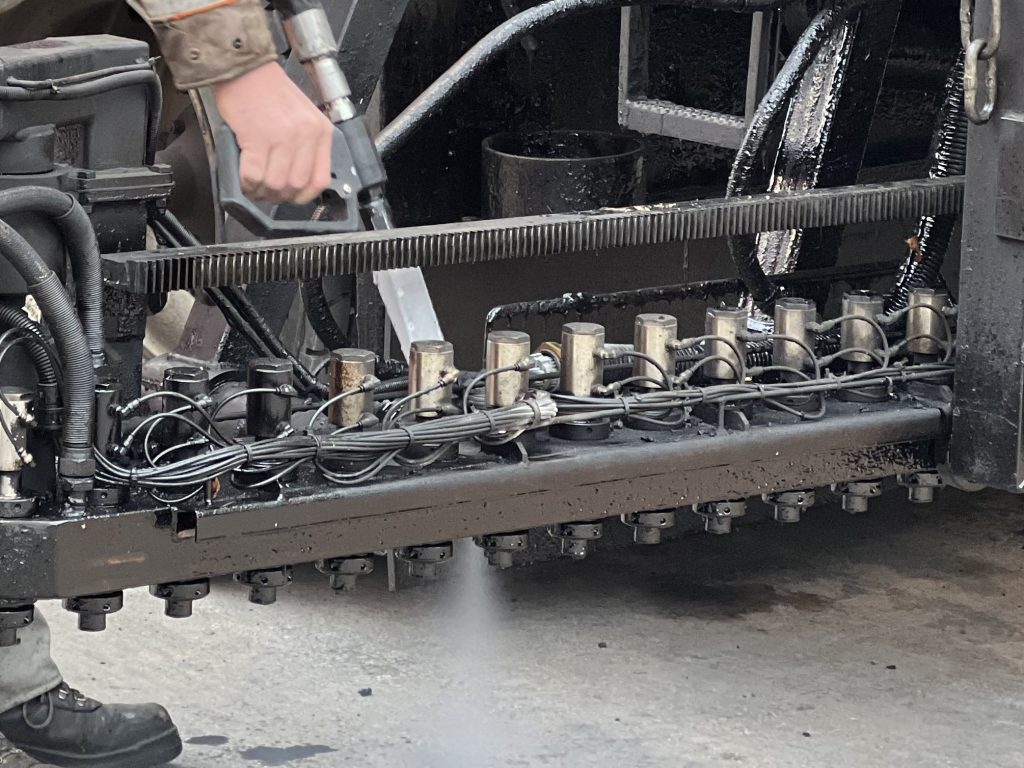

The cleaning effect of dry ice blasting technology is based on two main factors: the temperature difference and the thermal shock. When the dry ice hits the bitumen, it cools it quickly and causes brittle deformation. The sudden change in temperature causes the bitumen to loosen and break off without damaging the underlying materials. At the same time, small particles of bitumen are shot out by the high-pressure jet, which further optimizes the cleaning process. The sublimation of the dry ice leaves behind only a small amount of carbon dioxide, which is released into the air and therefore does not require solid waste disposal.

Useful information about dry ice, dry ice blasting machines, dry ice blasting systems and dry ice cleaning is conveniently available in our quarterly “Dry Ice News”. Please add your e-mail address to register without obligation. You can revoke your consent at any time with effect for the future. For information on the processing of your data, including for the improvement of our services, please refer to our data protection information.

The dry ice blasting process is particularly efficient in industry, especially when cleaning machines, production lines and storage areas where bitumen deposits are frequently found. This technology is also proving to be a valuable solution for the remediation of contaminated sites and the dismantling of industrial plants. An additional advantage is that no further preparation or post-processing steps are usually necessary, which saves time and money.

Another advantage of this method is its high level of thoroughness. As the dry ice is used in the form of small pellets, it can also penetrate hard-to-reach areas where other cleaning methods have difficulties. This is particularly relevant in the construction industry, where precise cleaning of surfaces is of great importance.

You can also reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information