White Lion | Dry ice blasting machine | Dry ice guide | Dry ice production

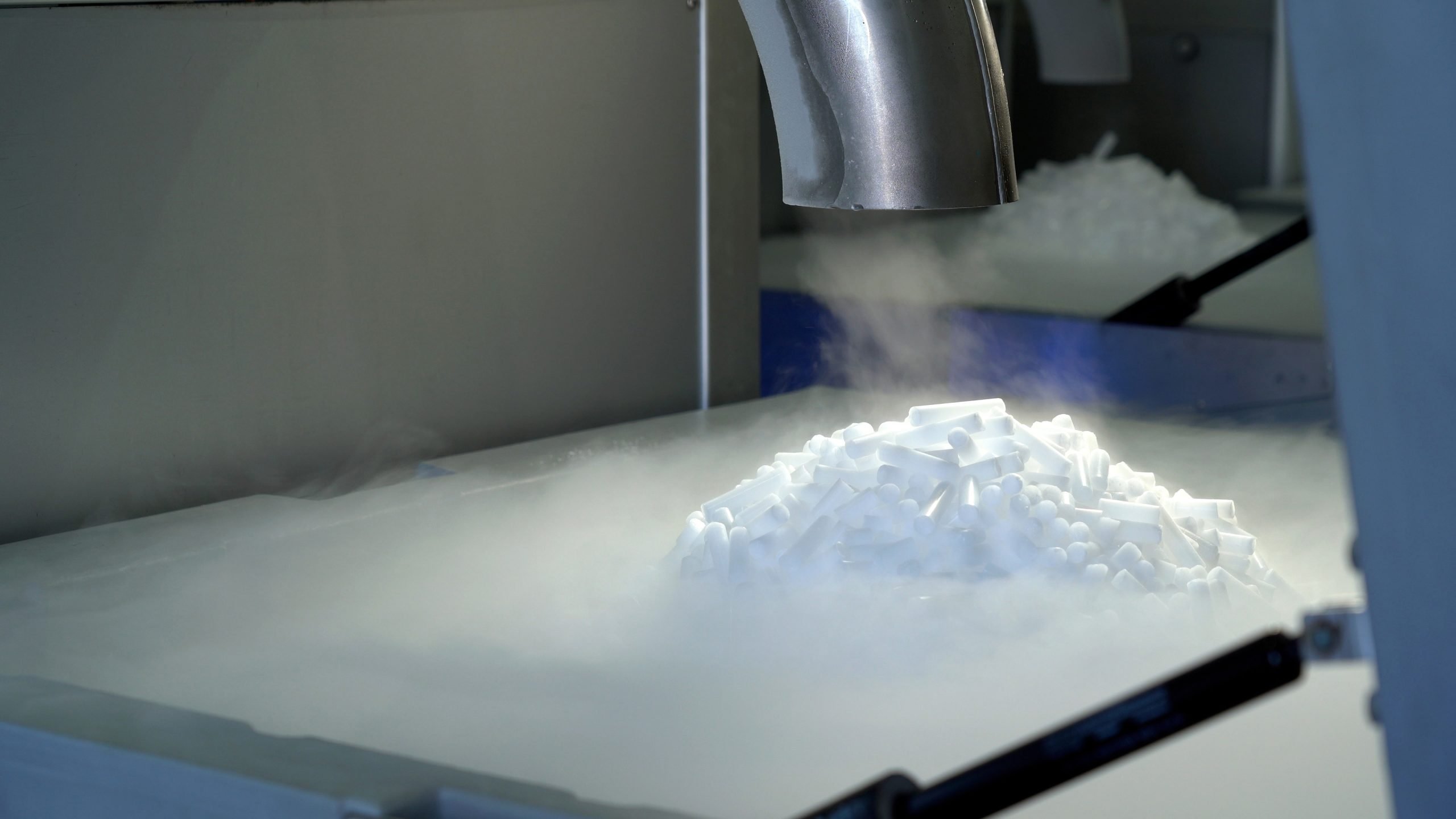

Dry ice has established itself as an indispensable product in many industries, be it in the food industry, the medical sector or at events and in the entertainment industry. The demand for this unique material is constantly growing and more and more companies are looking for a way to produce dry ice efficiently and cost-effectively in-house. In this guide, you will learn how dry ice is produced in a pelletizer and the benefits of investing in your own dry ice production.

Useful information about dry ice, dry ice blasting machines, dry ice blasting systems and dry ice cleaning is conveniently available in our quarterly “Dry Ice News”. Please add your e-mail address to register without obligation. You can revoke your consent at any time with effect for the future. For information on the processing of your data, including for the improvement of our services, please refer to our data protection information.

The decision to invest in their own dry ice production system opens up a wide range of benefits for companies. Above all, the cost savings play a decisive role. With their own system, companies have the opportunity to produce dry ice in line with demand, which leads to considerable savings in the long term.

In-house production also ensures greater flexibility. Production can be fully adapted to individual requirements, whether in terms of quantity or pellet size, which makes planning easier and saves valuable time.

Another advantage is the improved quality control. Thanks to in-house production, companies retain control over the entire manufacturing process and can therefore continuously monitor the quality of the dry ice. This ensures consistently high product quality.

If you regularly need large quantities of dry ice, we recommend our WL Antarctica S.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information