White Lion | Dry ice blasting machine | Patents & special machine construction

White Lion is setting new standards in the cleaning industry with its developments. The combination of innovative technology and a focus on sustainability makes the company a pioneer in its field. With the patents for laser cleaning and the expansion options for dry ice blasting systems, White Lion impressively demonstrates how modern technology and environmentally conscious action can go hand in hand. The future of industrial cleaning lies in these early innovations, which not only increase efficiency but also make a positive contribution to environmental protection.

One particularly noteworthy innovative step is the development of a module for expanding existing dry ice blasting systems into a solid abrasive system. With this modular approach, companies can customize and expand their cleaning processes to effectively remove different types of contamination. Converting to a solid abrasive system offers a wide range of benefits, including greater flexibility in use and improved efficiency when cleaning complex surfaces and geometric shapes.

You can reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

At airports, intensive rubber abrasion occurs during regular flight operations, particularly when aircraft land, regardless of type and size, especially on the main landing gear. The heavier the landing aircraft and the busier the airport, the faster a layer of rubber builds up on the runway, which has to be removed regularly.

This is absolutely essential for flight safety reasons.

Rubber-covered runways can significantly impair the braking effect, especially in wet conditions, snow or slush. A continuous layer of rubber also makes it difficult for water to run off in the grooves of the runway, which can result in the tires having little contact with the surface. In such cases, “hydroplaning” can occur, where water between the tires and the runway jeopardizes control of the aircraft. Viscous hydroplaning in particular can occur on very dirty runways, even with thin films of water and at different speeds. Some landing accidents and “runway overshoots” have been favored by this circumstance.

The rubber contamination is increasingly concentrated in the so-called “touch down zones”, i.e. the areas where the aircraft touch down. This typically affects the first 900 meters of the runway in both approach directions. For this reason, it is necessary to regularly remove the rubber layer in these zones, which can be done every 14 days at large commercial airports.

The conventional method of cleaning track surfaces has several disadvantages. These include high costs, which can affect profitability, and dependence on weather conditions, which often make it difficult to carry out the work. In addition, this method has an abrasive effect on the track surface, which can have a negative impact on its service life. Long cleaning intervals are another drawback, as they make regular maintenance of the surfaces more difficult. These challenges are rounded off by the additional disposal costs for the rubber waste generated during cleaning.

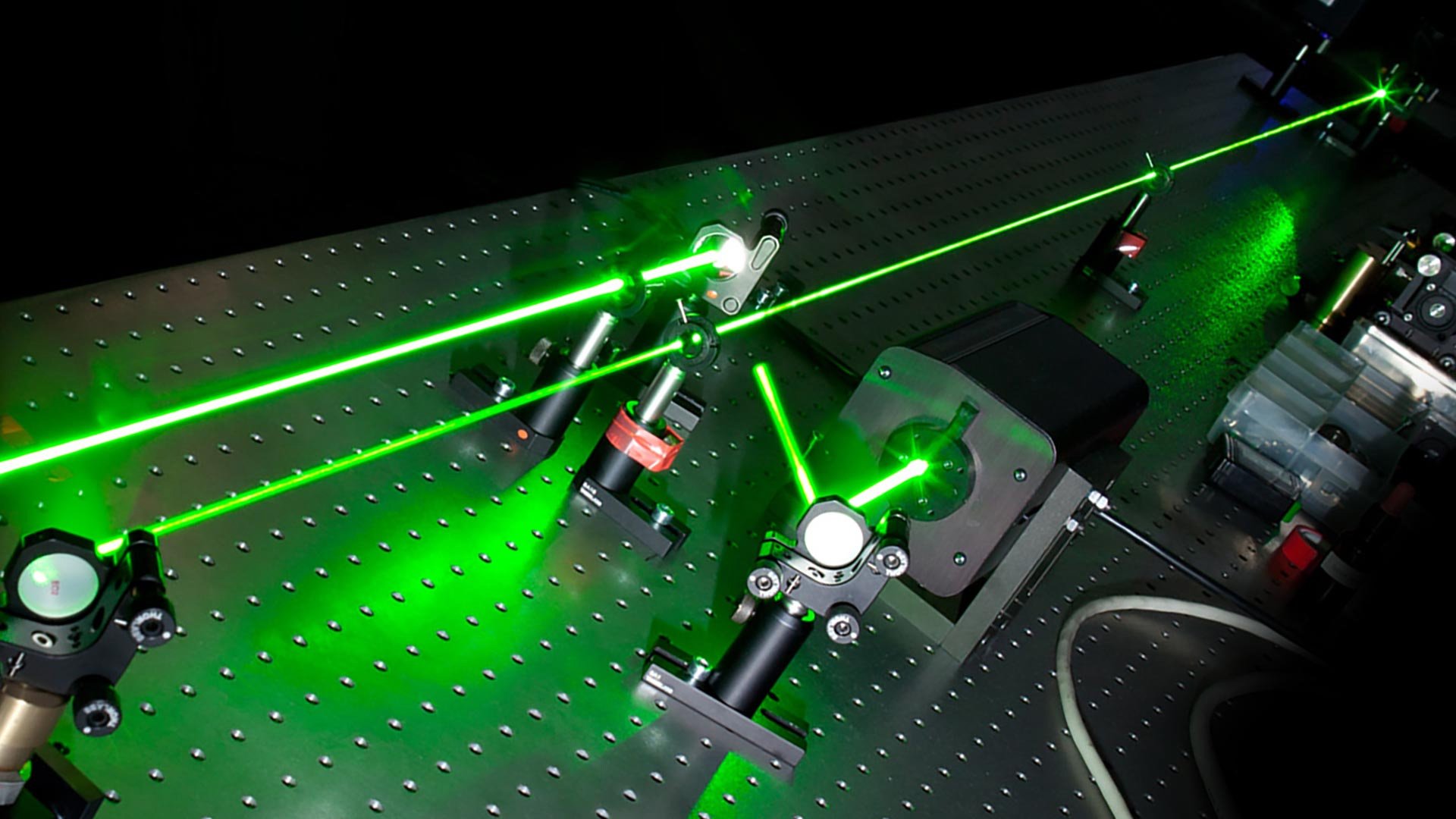

The laser blasting process for cleaning offers numerous advantages. In this process, a generated laser beam hits the track surface in the touch down zone. The specific frequency of the laser causes only the rubber coating to react and vaporize or burn off with high energy on contact with the laser beam. The resulting vapours are immediately captured by an extraction unit and neutralized by a catalyst. An ultrasonic system measures the coating thickness before and after cleaning and documents the results. This data archiving is used for quality assurance and proves the proper condition of the runway.

The operating costs of a laser system are considerably lower than those of the traditional method, while handling is much more convenient. This allows the laser system to be used more frequently, even weekly or daily, to keep the runway in a high state of cleanliness at all times. This increases the safety of the landing process and flight operations as a whole, as optimum traction can be guaranteed at all times. The cleaning laser can be used in all weather conditions, as it works over water, ice or snow and also works at temperatures below freezing.

The laser system is based on a specialized vehicle equipped with a variety of technical components. These include a laser system specially designed to remove rubber abrasion. Ultrasonic systems are also integrated to ensure precise coating thickness measurement before and after cleaning. An effective extraction system ensures that residues are collected and exhaust gases are filtered. Finally, a computer system enables the measurement data to be archived to ensure comprehensive documentation.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information