We see ourselves as a system supplier to the dry ice cleaning industry. On the one hand, this refers to the development and sale of blasting equipment in the field of dry ice blasting and dry ice production, the execution of cleaning work as well as the production of dry ice and the manufacture and sale of dry ice transport containers.

We at White Lion are experts when it comes to dry ice cleaning. With over 25 years of experience in the application and development of solutions for this cleaning technology, we have developed into one of the most competent providers on the market. The powerful cleaning performance of our blasting systems is always worth the price.

Dry ice cleaners make use of the special properties of dry ice for the efficient cleaning of surfaces, machines and plant technology. To do this, the device mixes pellets with compressed air and blasts them out of a nozzle at high speed.

The dry ice pellets are filled into the machine’s container, which is fitted with a glass lid. The glass makes it easy to check the fill level without having to open the lid and allowing warm air to enter the container. This prevents ground fog, which would obstruct the view of the fill level. Dry ice cleaners must be connected to a supply of compressed air and a standard power connection to a mains supply (230V / 50 Hz).

When operating the device, the blasting material mixes with the compressed air. The greater the amount of air and dry ice in combination with the air pressure, the greater the cleaning effect. This mixture is ejected into a hose package. The user can control the discharge of the dry ice and compressed air mixture via a blasting gun at the end of the hose package. Different nozzles can be used to shape the dry ice jet to suit the application. Round nozzles eject the dry ice pellets in a very concentrated manner and are suitable for particularly stubborn soiling. Large areas can be treated with flat nozzles. We will be happy to advise you on the selection of suitable accessories.

With dry ice cleaners from White Lion, the blasting pressure and pellet delivery rate can be infinitely adjusted. With the gentlest setting of 20 kg delivery volume in combination with a dry ice splitter, even particularly sensitive workpieces, such as electrical assemblies, can be cleaned without damaging them. With the maximum of 120 kg (model WL 3000) or 140 kg (model WL 5000 and WL 3000 Iron), even the most stubborn dirt can be removed quickly and efficiently from complex surfaces.

The compact design and easy handling of the blasting units open up a wide range of possibilities for use in dry ice blasting.

You can reach us during our office hours (08:00 to 16:00) by telephone on 0 61 51 / 60 66 82 0

100% availability is our service concept and high availability and reliability of your dry ice blasting system is the result.

Dry ice cleaning is an innovative process that is becoming increasingly important in many industries due to its many advantages. The blasting material are pellets of dry ice made from liquid CO. The blasting material is blasted onto the surface to be cleaned. The pellets create an explosive effect that causes the dirt to flake off the surface without damaging it. This means that even sensitive surfaces, e.g. electronic components, can be cleaned professionally, in contrast to conventional methods. After the blasting agent hits the surface, it is converted directly into a gaseous state, so there is no secondary waste that has to be disposed of at great expense.

This process enables economical cleaning with an effective result of cleanliness by providing a mobile or stationary method with maximum gentleness to remove dirt and contaminants without the use of additional chemicals, making it an increasingly popular choice in many industries.

Industrial cleaning does not necessarily have the reputation of being an environmentally friendly business, and not without good reason. High-pressure water blasting, for example, consumes an enormous amount of water and the waste water contaminated with cleaning agents and chemicals often has to be treated at great expense. In addition, chemical cleaning processes often produce harmful vapors from solvents and reaction products.

With dry ice blasting, there is no need to pollute the environment with chemicals or solvents. During cleaning with dry ice, the user is not exposed to any substances that are harmful to health.

Only liquid CO from natural sources is used for the production of dry ice. The consumption of dry ice is climate-neutral, there is no consumption of non-renewable resources, no greenhouse effect and no contaminated blasting residues.

Consistently clean surfaces are a very important part of any coating. Clean is by no means clean enough. The surface quality prior to finishing places high demands. The result of cleaning a surface must be free of grease, fingerprints and micro-particles before it can be coated.

Cleaning with fully automated, innovative blasting machines is an effective solution for pretreating surfaces. All relevant parameters such as compressed air, volume and abrasive as well as size and throughput can be determined separately. This also applies to the processing speed. This variable control achieves a flawless surface for every type of further processing. The White Lion equipment for the automated process speaks every robot language, so any commercially available robot can be combined with the system.

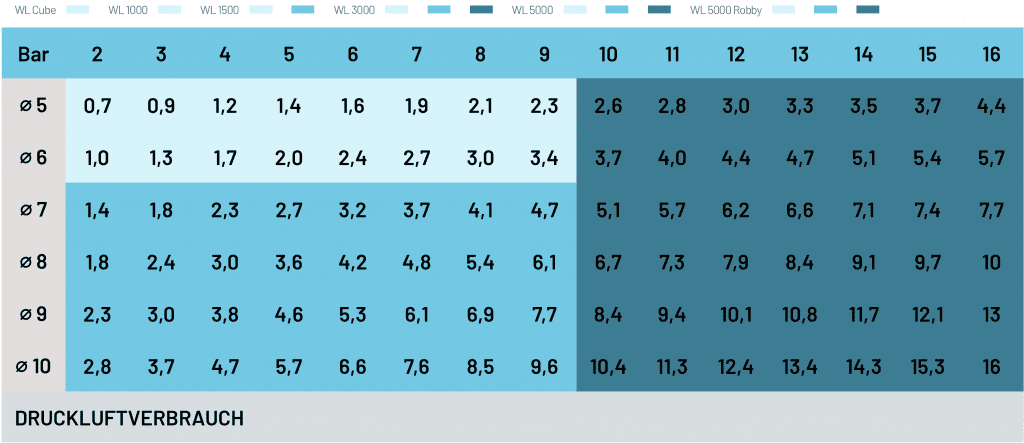

| Bar | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| ⌀ 5 | 0,7 | 0,9 | 1,2 | 1,4 | 1,6 | 1,9 | 2,1 | 2,3 | 2,6 | 2,8 | 3,0 | 3,3 | 3,5 | 3,7 | 4,4 |

| ⌀ 6 | 1,0 | 1,3 | 1,7 | 2,0 | 2,4 | 2,7 | 3,0 | 3,4 | 3,7 | 4,0 | 4,4 | 4,7 | 5,1 | 5,4 | 5,7 |

| ⌀ 7 | 1,4 | 1,8 | 2,3 | 2,7 | 3,2 | 3,7 | 4,1 | 4,7 | 5,1 | 5,7 | 6,2 | 6,6 | 7,1 | 7,4 | 7,7 |

| ⌀ 8 | 1,8 | 2,4 | 3,0 | 3,6 | 4,2 | 4,8 | 5,4 | 6,1 | 6,7 | 7,3 | 7,9 | 8,4 | 9,1 | 9,7 | 10 |

| ⌀ 9 | 2,3 | 3,0 | 3,8 | 4,6 | 5,3 | 6,1 | 6,9 | 7,7 | 8,4 | 9,4 | 10,1 | 10,8 | 11,7 | 12,1 | 13 |

| ⌀ 10 | 2,8 | 3,7 | 4,7 | 5,7 | 6,6 | 7,6 | 8,5 | 9,6 | 10,4 | 11,3 | 12,4 | 13,4 | 14,3 | 15,3 | 16 |

| DRUCKLUFTVERBRAUCH | |||||||||||||||

Compressed air consumption in m3/min. – Pressure data in bar – ⌀ = nozzle diameter 0.5 m3 (0.7 + 0.5 = 1.2 m3)

Compressed air is required for cleaning with a dry ice blasting system. You can rent or buy a suitable compressor. We work closely with reliable partners and can therefore always guarantee the best prices, regardless of whether you buy or rent a compressor.

We also reliably supply you with dry ice blasting material throughout Germany. We supply the dry ice in high-quality, well-insulated containers, which you can purchase or rent.

Sometimes it is not worth buying a dry ice blasting system or renting equipment for dry ice cleaning. If the cleaning intervals are too long or a company does not have its own resources to carry out dry ice cleaning, buying or renting is not efficient. In this case, we can take over the cleaning for you. We plan and carry out the cleaning carefully and flexibly, to your advantage and tailored to your needs.

With us, you can buy more than just a high-quality device for dry ice cleaning. We attach great importance to a reliable and trusting relationship with our customers. We are happy to assist you with your task and support you with service and advice.

White Lion is about more than just selling equipment. We look forward to supporting you in your success. We look forward to hearing from you and will be happy to work with you to put together a customized offer!

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information