White Lion | Blasting Alliance | Dry ice cleaning | Cleaning materials/materials | Clean plastic

The ubiquitous use of plastics extends across numerous areas, from packaging and components to complex technical applications. Thanks to their durability and resistance to numerous chemical influences, plastics have become indispensable in industry, construction, the automotive sector and consumer goods. These properties offer numerous advantages, but also pose challenges in terms of cleaning and maintenance. This is where innovative dry ice cleaning comes into play.

In contrast to traditional cleaning methods, which often require aggressive chemicals, dry ice blasting technology uses carbon dioxide in solid form. During cleaning, the dry ice sublimates and leaves no harmful residue behind. This is particularly relevant in environments where plastic parts come into contact with food or sensitive appliances. Here, it is essential not to use chemical cleaning agents in order to ensure safety and harmlessness.

In addition, the reuse and recycling of plastics is playing an increasingly important role in today’s world. The gentle cleaning technology of dry ice can help to significantly extend the service life of plastic components. By cleaning and reusing them efficiently, not only can the quality of the products be maintained, but the volume of waste can also be sustainably reduced. This makes dry ice cleaning not only an effective solution to the challenges of cleaning, but also a crucial building block for an environmentally conscious economy.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

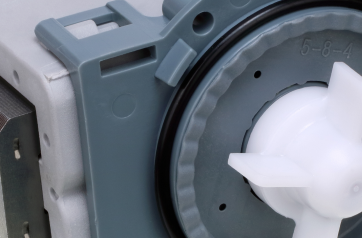

Dry ice blasting technology is an ideal solution for cleaning complex plastic components in vehicles. It enables thorough removal of contaminants even from hard-to-reach areas without damaging the sensitive material. By using dry ice, even the finest residues of lubricants, paint or other deposits are effortlessly removed, improving the functionality and appearance of the components. This gentle method not only contributes to the longevity of the plastic components, but also increases the efficiency of the entire production process.

Useful information about dry ice, dry ice blasting machines, dry ice blasting systems and dry ice cleaning is conveniently available in our quarterly “Dry Ice News”. Please add your e-mail address to register without obligation. You can revoke your consent at any time with effect for the future. For information on the processing of your data, including for the improvement of our services, please refer to our data protection information.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information