White Lion | Blasting Alliance | Dry ice cleaning | Remove impurities | Remove dust

One of the main areas of application for the dry ice blasting process for dust removal is machine and system cleaning in industry. In production facilities where dusty materials are processed – such as in the food, pharmaceutical or electronics industries – it is crucial to keep equipment clean to avoid contamination and ensure machine efficiency. Dry ice blasting makes it possible to remove dust quickly and thoroughly from hard-to-reach areas, such as the inside of machines, filters or housings.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

Many surfaces, such as machinery, electrical equipment or historical artifacts, can be covered in a thick layer of dust, dirt and debris. These impurities not only impair the appearance, but can also jeopardize the functionality and longevity of the materials.

There is an impressive difference after dry ice blasting: the surfaces shine in new splendor. Dry ice blasting not only removes dust, but also other stubborn residues without damaging the material. The method is chemical-free and leaves no residue as the dry ice evaporates on contact. The process therefore not only ensures thorough cleaning, but also protects the environment.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

Another important area is the cleaning of sensitive surfaces and devices, such as those found in medical technology. Here, it is essential that no residues remain on the devices that could impair functionality or jeopardize hygiene standards. Dry ice blasting is particularly advantageous as it works without water or chemical residues, minimizing the risk of corrosion or damage to sensors.

In the field of monument preservation and restoration, the dry ice blasting process is also used to remove dust and deposits from historical artifacts or buildings. As the technique is gentle and non-abrasive, it is ideal for sensitive materials such as stone, wood or metals. Restorers can thus eliminate superficial contamination without damaging the original structure or finish of the objects.

Another area of application can be found in the automotive industry, where dry ice blasting is used to remove dust and dirt from vehicle components. Particularly when cleaning engines, gearboxes or car bodies, this method can help to increase the efficiency of maintenance and extend the service life of components. The ability to thoroughly clean even hard-to-reach areas makes the process the preferred method for technical overhauls and repairs.

Useful information about dry ice, dry ice blasting machines, dry ice blasting systems and dry ice cleaning is conveniently available in our quarterly “Dry Ice News”. Please add your e-mail address to register without obligation. You can revoke your consent at any time with effect for the future. For information on the processing of your data, including for the improvement of our services, please refer to our data protection information.

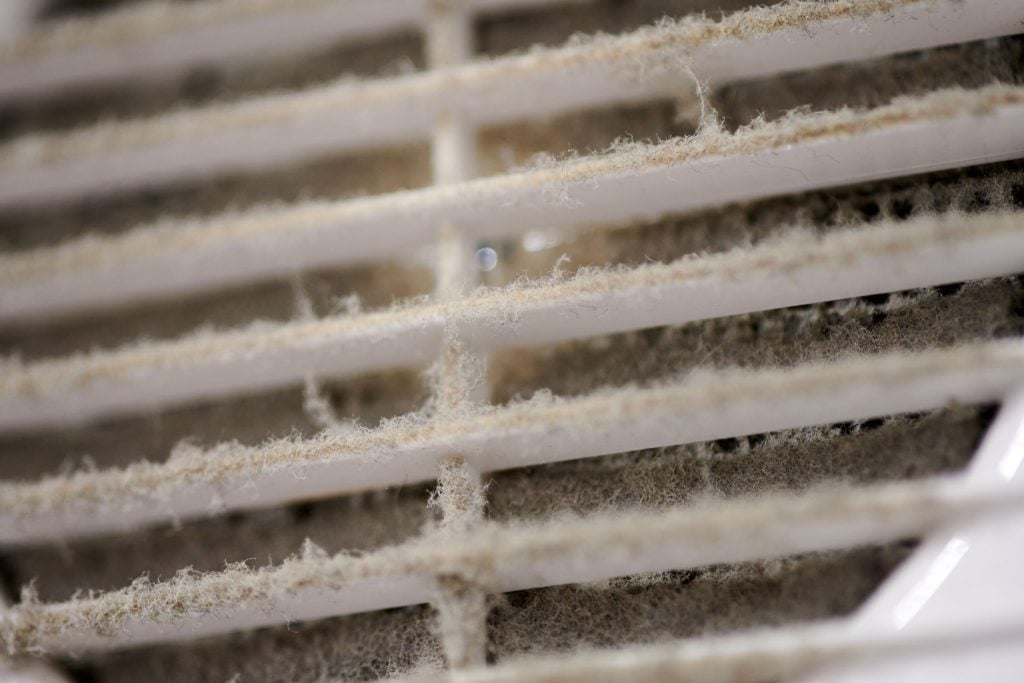

An important field of application for dry ice cleaning is the maintenance of computer hardware, with a particular focus on cleaning cooling systems, mainboards and graphics cards. The targeted and gentle removal of dust accumulations not only considerably increases the cooling performance of these components, but also significantly reduces the risk of overheating.

The cooling systems in computers are critical to performance as they ensure that the temperature of the components remains within an optimal range. Dust build-up can significantly affect the efficiency of these cooling systems by blocking airflow and making heat dissipation difficult. Dry ice cleaning offers an effective solution as it solves the problem of dust without leaving any residue or damage. The use of dry ice enables precise cleaning even in hard-to-reach areas.

You can also reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information