White Lion | Blasting Alliance | Dry ice cleaning | Remove impurities | Remove oil

The dry ice blasting process has established itself as a highly effective method for efficiently removing oil contamination from surfaces, particularly in the factory, plant engineering and automotive industries. It enables thorough, environmentally friendly cleaning directly on site without the need for dismantling, saving time and money while ensuring operational efficiency and hygiene in sensitive industries.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe use of traditional cleaning methods, such as chemical solvents or high-pressure cleaning, often leaves a greasy residue or damages sensitive surfaces. Cleaning is time-consuming and often requires additional post-treatment.

After using the dry ice blasting process, the treated surface is impressively clean. The dry ice sublimates on contact with the surface, which means that it turns into a gaseous state, removing the oil residue without leaving any residue or damaging the surface. The process is also environmentally friendly, as no harmful chemicals are used and cleaning is quick and efficient.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

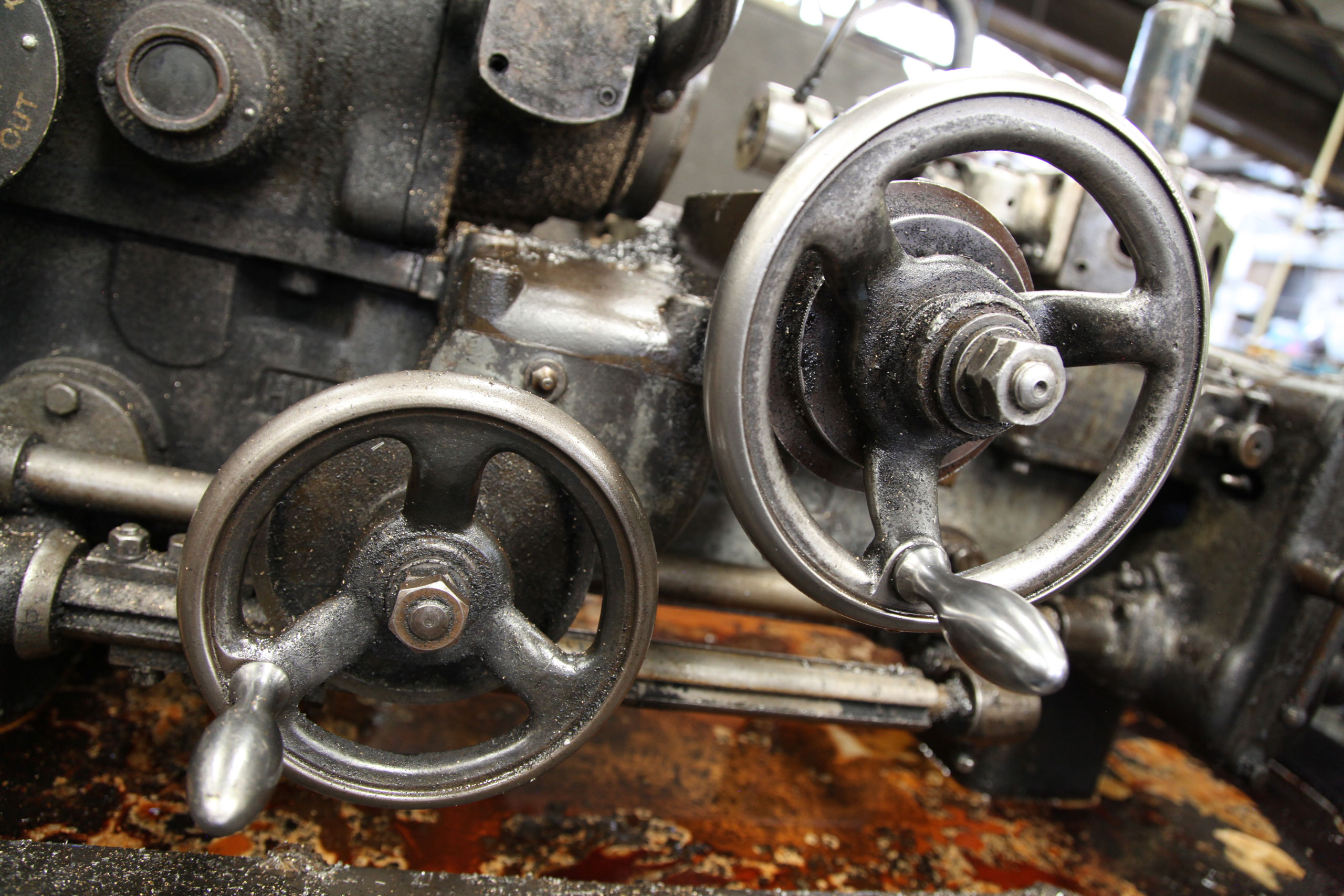

The dry ice blasting process has established itself as an extremely effective method for removing oil contamination from a wide variety of surfaces. It plays a key role in factory and plant engineering in particular. In industrial plants, where machines and equipment are often contaminated with oil, dry ice blasting enables thorough cleaning directly on site. This is done without time-consuming dismantling, which saves time and money and significantly increases operating efficiency.

Another important area of application is in the automotive industry. The removal of oil from engines and other vehicle components is essential for maintenance and servicing work. Dry ice blasting not only ensures thorough cleaning, but also improves visibility for subsequent inspections. This helps to identify potential problems at an early stage and ensure vehicle safety.

In the food industry, where the highest standards of hygiene are required, dry ice blasting also offers considerable advantages. The method makes it possible to remove oil and grease from machines and surfaces without the risk of contaminating the food. As a result, it meets rigorous hygiene requirements and ensures a clean production process, which is of the utmost importance for maintaining quality and safety.

The dry ice blasting process is also indispensable in foundries and mechanical engineering. Here it is used to clean molds and equipment by ensuring that process carriers remain oil-repellent. This not only increases product quality, but also minimizes downtime and reduces the need for costly reworking.

Useful information about dry ice, dry ice blasting machines, dry ice blasting systems and dry ice cleaning is conveniently available in our quarterly “Dry Ice News”. Please add your e-mail address to register without obligation. You can revoke your consent at any time with effect for the future. For information on the processing of your data, including for the improvement of our services, please refer to our data protection information.

The advantages of the dry ice blasting process are manifold and range from environmental friendliness and efficiency to the protection of surfaces. The use of dry ice, which leaves no waste material behind when it evaporates, not only protects the environment but also promotes the longevity of the cleaned surfaces.

Due to its versatility and ability to be used successfully in various industries, this process is an increasingly preferred choice for professional cleaning applications. The combination of cost-effectiveness and ecological responsibility makes dry ice blasting a forward-looking solution in the field of machine cleaning and oil removal.

You can also reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information