Dry ice is our profession and has been for many years. This makes us one of the pioneers of this highly effective cleaning technology. We know the industry from every angle and our dry ice blasters have been developed based on our experience with this technology in daily use. This makes our machines particularly precise and optimal in terms of performance and handling. Dry ice cleaning is simple, fast and efficient with our machines.

Dry ice blasters are available in many different quality levels. We specialize in the manufacture of extremely robust and universally applicable machines. We manufacture the frames of our devices from high-strength, welded stainless steel or bolted aluminum profiles. We also use stainless steel or aluminum metal for the housing, so our machines are always protected against corrosion. Stainless steel and aluminum are an optimal choice for a dry ice blaster, as these corrosion-free materials provide lasting and reliable protection for the inner workings, even under harsh conditions. Spot heat, acids, alkalis or other mechanical or chemical attacks do not affect these housings. This makes our dry ice cleaners particularly versatile, especially in the industrial sector.

Dry ice blasting machines from White Lion do not have to be elaborately coated, but can withstand a rain shower without rusting. Our machines impress with a very long service life.

For us, quality also means all-round service. We guarantee a stock of all spare parts for every appliance for many years.

If your blasting system breaks down, we take care of the entire process. We will collect your system to be repaired using our own logistics or a forwarding agent. We will provide you with an equivalent system for the duration of the service period so that you do not suffer any downtime.

You can reach us during our office hours (08:00 to 16:00) by telephone on 0 61 51 / 60 66 82 0

100% availability is our service concept and high availability and reliability of your dry ice blasting system is the result.

Compressed air is required for dry ice blasting. The compressed air is mixed with the blasting material, dry ice pellets, in the dry ice blasting system and blown out via a blasting hose and a nozzle. This requires a filling container for the dry ice and a device to regulate the working pressure. With an infinitely variable, adjustable working pressure, the dry ice blaster can always be used to suit the situation. The tank and pressure reducer are therefore integral components of a high-quality system. A

With a reliable compressed air supply from a suitable compressor, excellent performance can be achieved from our systems. There is a large selection of compressors in every price class. You can rent them or lease or finance them through our financial partners. We will be happy to advise you on the choice of compressor for the optimum supply of air required for mobile and stationary dry ice cleaning applications.

With its modular design, a dry ice blaster can be used for many applications. Our extensive range of accessories includes hoses in various lengths, blasting guns and a wide selection of nozzles. The choice of nozzles with different cross-sections, shapes and diameters gives the user the necessary freedom to always have the right tool to hand for the surface to be cleaned. The right choice of accessories is crucial for successful dry ice cleaning and a strong cleaning performance. A nozzle extension can make floor cleaning much more ergonomic, effective and therefore more economical. Sensitive surfaces can be cleaned gently and effectively with the right accessories.

We will be happy to advise you on the right accessories for your cleaning.

Wear long-sleeved work clothing, safety goggles, gloves and hearing protection when working with dry ice. When using dry ice blasting in cellars or shafts, additional ventilation is required. We will be happy to instruct you on how to use a White Lion dry ice blaster and explain all the dangers and how to deal with them.

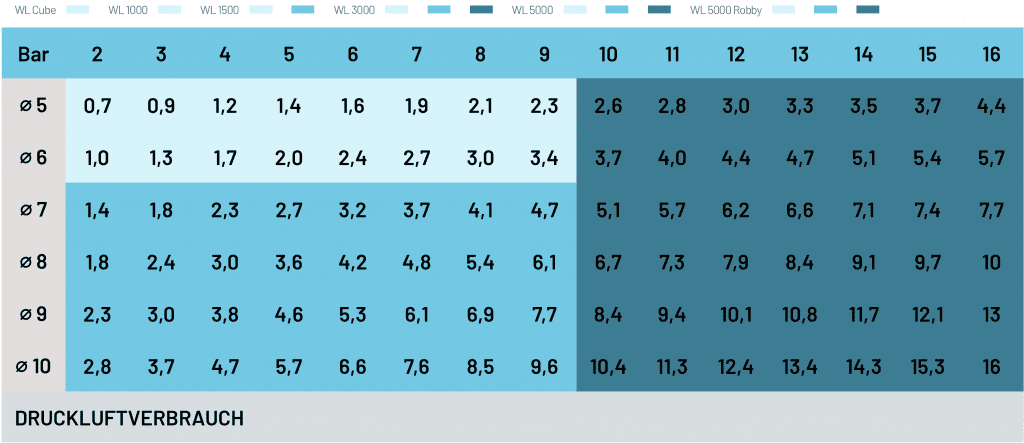

| Bar | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| ⌀ 5 | 0,7 | 0,9 | 1,2 | 1,4 | 1,6 | 1,9 | 2,1 | 2,3 | 2,6 | 2,8 | 3,0 | 3,3 | 3,5 | 3,7 | 4,4 |

| ⌀ 6 | 1,0 | 1,3 | 1,7 | 2,0 | 2,4 | 2,7 | 3,0 | 3,4 | 3,7 | 4,0 | 4,4 | 4,7 | 5,1 | 5,4 | 5,7 |

| ⌀ 7 | 1,4 | 1,8 | 2,3 | 2,7 | 3,2 | 3,7 | 4,1 | 4,7 | 5,1 | 5,7 | 6,2 | 6,6 | 7,1 | 7,4 | 7,7 |

| ⌀ 8 | 1,8 | 2,4 | 3,0 | 3,6 | 4,2 | 4,8 | 5,4 | 6,1 | 6,7 | 7,3 | 7,9 | 8,4 | 9,1 | 9,7 | 10 |

| ⌀ 9 | 2,3 | 3,0 | 3,8 | 4,6 | 5,3 | 6,1 | 6,9 | 7,7 | 8,4 | 9,4 | 10,1 | 10,8 | 11,7 | 12,1 | 13 |

| ⌀ 10 | 2,8 | 3,7 | 4,7 | 5,7 | 6,6 | 7,6 | 8,5 | 9,6 | 10,4 | 11,3 | 12,4 | 13,4 | 14,3 | 15,3 | 16 |

| DRUCKLUFTVERBRAUCH | |||||||||||||||

Compressed air consumption in m3/min. – Pressure data in bar – ⌀ = nozzle diameter 0.5 m3 (0.7 + 0.5 = 1.2 m3)

The advantage of cleaning with dry ice is that this process can remove dirt very effectively and gently at the same time, as it is not an abrasive blasting process. No damage is caused and even polished surfaces can be cleaned. During dry ice cleaning, the dirt is simultaneously loosened and blown away by the pellets at high speed and the pellets immediately turn into a gaseous state under high pressure, meaning that no further subsequent process is required.

The soiling can be completely removed by the dry ice pellets, leaving an intact surface.

The advantages of dry ice blasting over conventional blasting methods are manifold. The process saves time and money. The parts to be cleaned do not need to be dismantled for cleaning and can therefore also be cleaned during operation. Even electrical components can be cleaned using the dry ice blasting process, as the blasting material is not electrically conductive.

Dry ice cleaning combines powerful cleaning performance with maximum protection of surfaces, making it an ideal cleaning method for industry in particular.

No dry ice blasting machine works without dry ice. You can buy the blasting material externally, but a dry ice production machine, a pelletizer, makes sense for high consumption quantities. Our WL Antarctica dry ice machine provides the necessary supply of blasting material. Depending on the machine, 120 to 240 kg of blasting material can be produced per hour in different types of dry ice. This means you are permanently supplied with fresh dry ice.

We are a manufacturer and developer of high-quality dry ice production systems and dry ice blasting systems. Our product portfolio includes all equipment for dry ice blasting: Dry ice blasting machines, robot systems for automated blasting, dry ice production systems, dry ice and an extensive portfolio of accessories. We are constantly developing our technology and taking new measures and ideas to improve our service, quality and customer satisfaction.

The areas of application for dry ice blasting technology are extremely diverse. Our team will provide you with expert advice and answer all your questions.

We offer a wide range of dry ice blasting machines and peripheral equipment in different price categories. The price of the system depends on what you need. Together we will prepare an individual offer with a complete package that is ideally suited to your application. We look forward to your call!

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information