Dry ice cleaning is a reliable solution for all challenges relating to the processing of surfaces. This innovative blasting process can be used for most types of soiling and cleans thoroughly and without consequential damage.

In dry ice cleaning, dry ice pellets are blasted onto the surface to be cleaned at high speed using compressed air. These remove stubborn dirt without the use of abrasive blasting agents and without damaging sensitive surfaces.

The use of conventional blasting materials such as sand or glass beads is still widespread for heavy soiling. However, these conventional blasting methods have two disadvantages: The material to be blasted can be attacked and destroyed by the abrasive blasting material. The second side effect is that the blasting material is not only blown onto the area to be cleaned, but everywhere. The abrasive has to be collected and disposed of. It also settles in corners, from which it has to be removed using other laborious cleaning methods. Although this does not happen when cleaning with the high-pressure water blasting method, the effectiveness of this method is limited and involves a high level of moistening of the blasted object and the surrounding area.

The advantage of a machine that uses dry ice as a blasting material is that no secondary waste is produced. The pellets used by the blasting system evaporate without leaving any residue. All that remains at the end is the flaked-off dirt. With this innovative blasting technology, all dirt can be gently removed. The dry ice blasting process cleans efficiently without causing damage during processing.

You can reach us during our office hours (08:00 to 16:00) by telephone on 0 61 51 / 60 66 82 0

100% availability is our service concept and high availability and reliability of your dry ice blasting system is the result.

The following three components are required to put a blasting system into operation: electricity, compressed air and dry ice. Electrical energy is required to operate the pump, the control system and the pellet conveyor. Compressed air is required to transport the dry ice. Finally, the dry ice blasting material is the active agent that ensures the cleaning performance. Operating a dry ice blasting system therefore requires a power supply unit, a compressor and a supply of dry ice pellets. This can either be purchased externally or produced in-house with a separate White Lion pelletizing machine.

Our product range includes systems for every application. We have the right blasting system for every area of application – whether for vehicle preparation, service providers, rental companies or industrial applications. We develop and build our blasting systems and pelletizing machines ourselves. When it comes to compressed air, we rely on the high quality of our high-performance partners. All our blasting systems can be used with any compressor. We offer you a customized solution for your challenge from a single source.

The performance of a blasting unit depends on its actual equipment and quality and on the compressed air supplied to the blasting system.

The quality is determined by the factors air volume, air pressure and humidity. The air volume and air pressure should be as high as possible; the air volume in conjunction with the air pressure is particularly decisive for the performance of dry ice blasting. Performance can suffer if the working pressure or air volume is low. The blasting system should be designed to match the air volume.

We are aware of this problem and therefore offer a wide range of ½, ¾ and 1 inch blasting systems to make dry ice blasting simple and flexible.

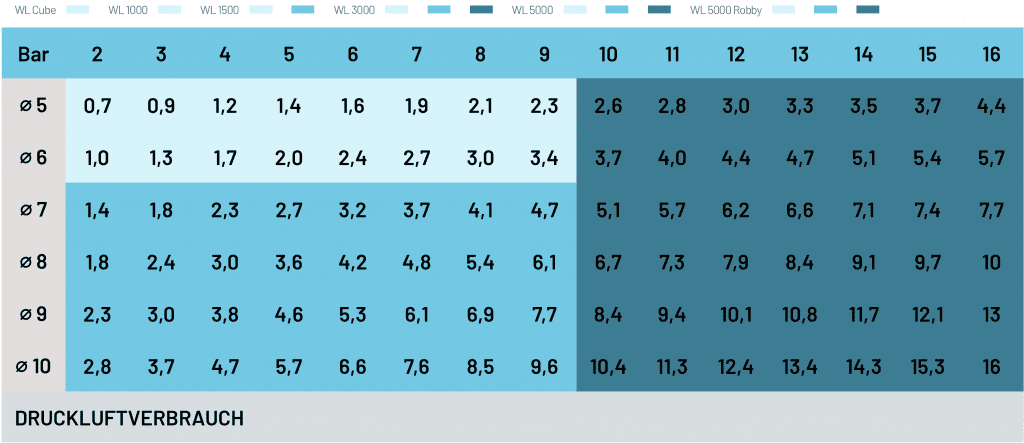

| Bar | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| ⌀ 5 | 0,7 | 0,9 | 1,2 | 1,4 | 1,6 | 1,9 | 2,1 | 2,3 | 2,6 | 2,8 | 3,0 | 3,3 | 3,5 | 3,7 | 4,4 |

| ⌀ 6 | 1,0 | 1,3 | 1,7 | 2,0 | 2,4 | 2,7 | 3,0 | 3,4 | 3,7 | 4,0 | 4,4 | 4,7 | 5,1 | 5,4 | 5,7 |

| ⌀ 7 | 1,4 | 1,8 | 2,3 | 2,7 | 3,2 | 3,7 | 4,1 | 4,7 | 5,1 | 5,7 | 6,2 | 6,6 | 7,1 | 7,4 | 7,7 |

| ⌀ 8 | 1,8 | 2,4 | 3,0 | 3,6 | 4,2 | 4,8 | 5,4 | 6,1 | 6,7 | 7,3 | 7,9 | 8,4 | 9,1 | 9,7 | 10 |

| ⌀ 9 | 2,3 | 3,0 | 3,8 | 4,6 | 5,3 | 6,1 | 6,9 | 7,7 | 8,4 | 9,4 | 10,1 | 10,8 | 11,7 | 12,1 | 13 |

| ⌀ 10 | 2,8 | 3,7 | 4,7 | 5,7 | 6,6 | 7,6 | 8,5 | 9,6 | 10,4 | 11,3 | 12,4 | 13,4 | 14,3 | 15,3 | 16 |

| DRUCKLUFTVERBRAUCH | |||||||||||||||

Compressed air consumption in m3/min. – Pressure data in bar – ⌀ = nozzle diameter 0.5 m3 (0.7 + 0.5 = 1.2 m3)

Each of our blasting systems can operate within a range of at least 10 bar compressed air. Our smallest unit, the WL Cube, is ready for operation from 0.5 bar. Our larger models can handle a maximum pressure of 16 bar. In terms of air volume, our smallest unit starts at 0.2 m³/min and our largest blasting unit can process up to 16 m³/min.

Heavy soiling on a sensitive surface of components or workpieces makes cleaning a costly and time-consuming task. This problem can be found in print shops, for example. With conventional blasting techniques, it is almost impossible to clean spilled paint on circuit boards and cable connections. With the right blasting system, a high-quality cleaning result can be achieved even in the most difficult cases. The build-up is removed without residue during dry ice cleaning and the underlying components or workpieces remain undamaged. The result is a device that looks as good as new.

Dry ice blasting is a universally applicable cleaning method. Even heavy soiling caused by bitumen, grease, oil, paint, varnish or other sticky residues can be completely removed from components and workpieces. The surface to be cleaned is spared during blasting.

Our blasting units impress with a particularly wide range of applications and usability under difficult conditions. The nature of a White Lion blasting machine is impressive due to its possible use in environments with aggressive acids or alkalis. The body of our systems is made of high-strength but lightweight aluminum or stainless steel, thus protecting the inner workings of the machine during dry ice blasting under harsh operating conditions.

Our compact blasting units are equally suitable for stationary and mobile applications. Our units are either portable or equipped with sturdy castors. This means they can be moved easily and conveniently to any desired location.

A dry ice blasting machine is a highly efficient cleaning device for versatile use. With our comprehensive expertise gained from over 25 years of experience, we are happy to advise you and offer our customers the right blasting system and accessories, such as nozzles, for their requirements.

Give us a call if you require further technical information or technical data on our systems. We will also be happy to provide you with an individual offer for your challenge.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information