White Lion | Dry ice blasting machine

As a manufacturer and seller of dry ice blasting machines, we offer you a wide selection of high-quality dry ice blasting machines that guarantee safe and gentle cleaning. Just like us, our carefully selected dealers and importers offer professional service and guarantee the best prices as well as close customer contact for any questions you may have.

Industrial companies, trading stations and service companies have good arguments for choosing a dry ice blasting machine. No other process achieves such fast and effective cleaning results as dry ice blasting. Whether in production, maintenance or building cleaning – with dry ice, optimum cleaning results are always achieved to your advantage.

At White Lion, you can buy your desired dry ice blasting machine either directly from us or from one of our selected dealers. We offer competitive prices without compromising on quality or service – always with satisfied customers in mind.

We attach great importance to trusting relationships with our customers and are happy to support them after the purchase with advice on all aspects of their purchased appliance. Our main target group are tradespeople, service providers and industrial companies with a need for such appliances, but private individuals are of course also very welcome.

Thanks to our network of certified dealers, interested parties not only receive expert advice on site, but also learn everything they need to know about safety and environmental protection.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

The selection of dry ice blasting systems from our company meets the requirement of being able to offer the right system for every application sector of the dry ice blasting process. With

Our dry ice blasting machines impress with many additional, very practical features. For example, the fill level of the dry ice pellets in White Lion dry ice blasting systems can be checked without having to open the lid. In this way, no fog escapes and blocks the view of the machine’s pellet fill level.

In the range of numerous types of industrial blasting equipment, dry ice blasting systems can be categorized between high-quality high-pressure cleaners and hard sandblasting blowers and are versatile in use. A White Lion dry ice blasting unit can be used to process areas that are too weak for a high-pressure cleaner and too sensitive for a sandblasting fan.

In addition to classic applications such as rust removal and paint stripping, the greatest strengths of dry ice cleaning lie in the cleaning sector. Numerous areas of application such as electrical systems, open circuit boards, machines from the food industry, upholstery or surfaces heavily covered in oil and dried paint are no problem for a dry ice blaster. Dry ice cleaning combines powerful cleaning performance with maximum surface protection.

The performance of a dry ice blasting system is impressive. Only unwanted adhesions are removed with precision. The underlying surface, no matter how sensitive it is, remains unaffected.

In the dry ice blasting process, as with any other blasting process, a blasting material is blown onto a surface at high speed using compressed air. The -78°C cold dry ice pellets, which are produced from liquid CO 2 , dissolve the unwanted soiling as soon as they hit the surface. Two other things happen when the dry ice pellets hit the surface. The dirt particles on the surface cool down considerably due to the low temperatures, making them brittle, hard and cracked. When it hits the warm surface, the dry ice vaporizes explosively into the aggregate state. The loosened adhering dirt is thus completely removed from the surface. Furthermore, no secondary waste is produced by the pellets, as the dry ice blasting material sublimates into a natural gas, which is a component of the ambient air. Compared to conventional blasting methods, dry ice cleans without leaving any residue, so there is no need for a cleaning operation lasting several hours. The result is practical and effective cleaning.

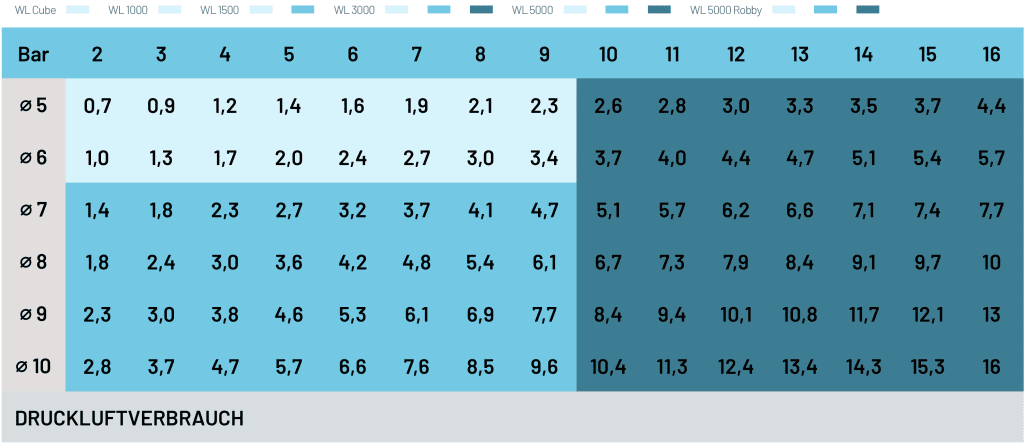

| Bar | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| ⌀ 5 | 0,7 | 0,9 | 1,2 | 1,4 | 1,6 | 1,9 | 2,1 | 2,3 | 2,6 | 2,8 | 3,0 | 3,3 | 3,5 | 3,7 | 4,4 |

| ⌀ 6 | 1,0 | 1,3 | 1,7 | 2,0 | 2,4 | 2,7 | 3,0 | 3,4 | 3,7 | 4,0 | 4,4 | 4,7 | 5,1 | 5,4 | 5,7 |

| ⌀ 7 | 1,4 | 1,8 | 2,3 | 2,7 | 3,2 | 3,7 | 4,1 | 4,7 | 5,1 | 5,7 | 6,2 | 6,6 | 7,1 | 7,4 | 7,7 |

| ⌀ 8 | 1,8 | 2,4 | 3,0 | 3,6 | 4,2 | 4,8 | 5,4 | 6,1 | 6,7 | 7,3 | 7,9 | 8,4 | 9,1 | 9,7 | 10 |

| ⌀ 9 | 2,3 | 3,0 | 3,8 | 4,6 | 5,3 | 6,1 | 6,9 | 7,7 | 8,4 | 9,4 | 10,1 | 10,8 | 11,7 | 12,1 | 13 |

| ⌀ 10 | 2,8 | 3,7 | 4,7 | 5,7 | 6,6 | 7,6 | 8,5 | 9,6 | 10,4 | 11,3 | 12,4 | 13,4 | 14,3 | 15,3 | 16 |

| DRUCKLUFTVERBRAUCH | |||||||||||||||

Compressed air consumption in m3/min. – Pressure data in bar – ⌀ = nozzle diameter 0.5 m3 (0.7 + 0.5 = 1.2 m3)

Contamination such as leaked paint, bitumen splashes, overflowing hot glue, old grease crusts, etc. could previously only be removed with great effort using a scraper or harsh solvents. Cleaning such soiling on cable trays or on a computer board with a spatula, brush, sandblasting or solvents is not feasible, as the components cleaned in this way ultimately have to be replaced. The solution here is residue-free dry ice cleaning. The use of a dry ice blasting device produces an extremely sensitive but also extremely thorough cleaning without damaging the surface to be cleaned in the slightest.

Dry ice cleaning with a dry ice blaster eliminates abrasive effects compared to conventional blasting methods. Heavy soiling can be removed gently and easily without any chemicals. Dry ice blasting cleans efficiently and quickly.

You can reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

The smallest of our dry ice blasting machines is our compact, mobile all-rounder from White Lion. Weighing just 45 kg, our WL Cube achieves impressive results thanks to a special combination of grinding unit for microparticles and dosing unit. Thanks to minimal compressed air consumption, the WL Cube operates with significantly lower noise emissions, depending on the application. With our Cube you are mobile and comfortable on the road.

Our WL 1500 Competition is a flexible and mobile dry ice blasting system and offers a respectable blasting performance with a blasting pressure of 10 bar and a consumption of 80 kg/hour of dry ice – ideal for beginners with a flexible performance spectrum.

With our WL 3000 series, we have a particularly versatile dry ice blasting unit for mobile and stationary use. Our powerful all-rounder WL 3000 Profi is ready for use in all areas of application and is the preferred dry ice blasting system in the service industry.

The 3000 series also consists of the WL 3000 Iron and the WL 3000 Black Edition. These have the same performance parameters as our 3000 Profi, differing only in shape, design and material.

Our WL 5000 Airmax in the ¾ and 1 inch versions is our answer for continuous, demanding use. With a delivery rate of up to 280 kg of dry ice, combined with a high volume of compressed air, this dry ice blasting system has been designed for the toughest industrial challenges.

The distinguishing feature of our WL 5000 Robby is its suitability for cleaning with robots. This device is equipped with a robot interface and sensors and is our solution for the automated process in surface technology. Direct filling via integrated dry ice production is also possible.

The decisive advantage of the simple handling of our dry ice blasting machines means that there are many possible applications for dry ice blasting.

As standard, our dry ice blasting machines are equipped with a hose package with a length of 5 to 10 meters, depending on the model. Other hose lengths are also available as an option. Power cable, a hose for the compressed air, blasting gun and blasting nozzle for maximum cleaning performance are also included with every device.

Various accessories are therefore available for dry ice blasting systems, which can help to increase the efficiency and safety of the application. Due to high demands, White Lion has invested in its own developments to help operators of blasting machines for cleaning with dry ice.

Our hose package is a blasting hose with a quick coupling system that enables the dry ice blasting unit to be connected to the blasting gun. These hoses are compatible with devices from other manufacturers.

Our product portfolio includes special nozzles and tools. These include nozzle attachments, cyclone separators and scramblers, which can be customized for specific applications. White Lion also offers customized solutions that precisely meet customer needs for dry ice cleaning.

Our blast gun is a specialized gun designed for use with our machines. The gun offers different sizes of air nozzles that are suitable for different blasting nozzle sizes.

Flat nozzles are used for processing large surfaces such as facades. The aggressiveness of the process can be determined by the size of the outlet; in addition, the blasting pattern can be optimized by adding the scrambler nozzle.

We also sell transport boxes that have been specially developed to transport dry ice safely. They offer plenty of space and excellent insulation to minimize sublimation loss during transport and preserve the quality of the dry ice.

The choice of accessories plays a decisive role in the efficient and safe use of dry ice blasting systems in various areas of application. We will provide you with detailed advice on the suitable accessories for your task.

The dry ice blasting systems from White Lion are used in industry and are suitable for a wide range of materials. Our products enable effective and gentle cleaning without water, chemicals or abrasive additives. Thanks to the non-abrasive and residue-free technology, even sensitive surfaces can be cleaned without damaging them.

Examples of suitable materials:

Our systems clean with frozen CO₂ in pellet form – known as dry ice – which is crushed into fine ice particles before being ejected. These dry ice particles are then blasted onto the soiled surface at high speed. On impact, the dry ice sublimates, i.e. it changes directly from a solid to a gaseous state. Neither moisture nor residues are produced.

The cleaning effect is created by the interaction of kinetic energy, the thermal shock caused by the cold and the volume expansion during the transition to the gaseous state. This means that even very stubborn soiling can be removed effectively and gently.

The process is dry, non-abrasive and ideal for reliably cleaning sensitive technology, fine surfaces or hard-to-reach areas – without any water or chemicals.

We are happy to advise you in detail and provide you with an individual offer tailored to your specific needs and requirements, including the selection of suitable accessories taking into account your specific area of application. If you have any questions about our devices and accessories, please do not hesitate to contact us by e-mail or telephone – of course you can also contact us via our website!

Our team of experts will be happy to provide you with personal and free advice. We are available around the clock and offer you support to find the ideal implementation for your specific requirements. Our aim is to provide you with the best possible solution to your cleaning problems, backed by our many years of experience and expertise.

It’s best to contact us right away. We look forward to your inquiry!

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information