White Lion | Dry ice blasting machine | Branches & Industries | Semiconductor industry

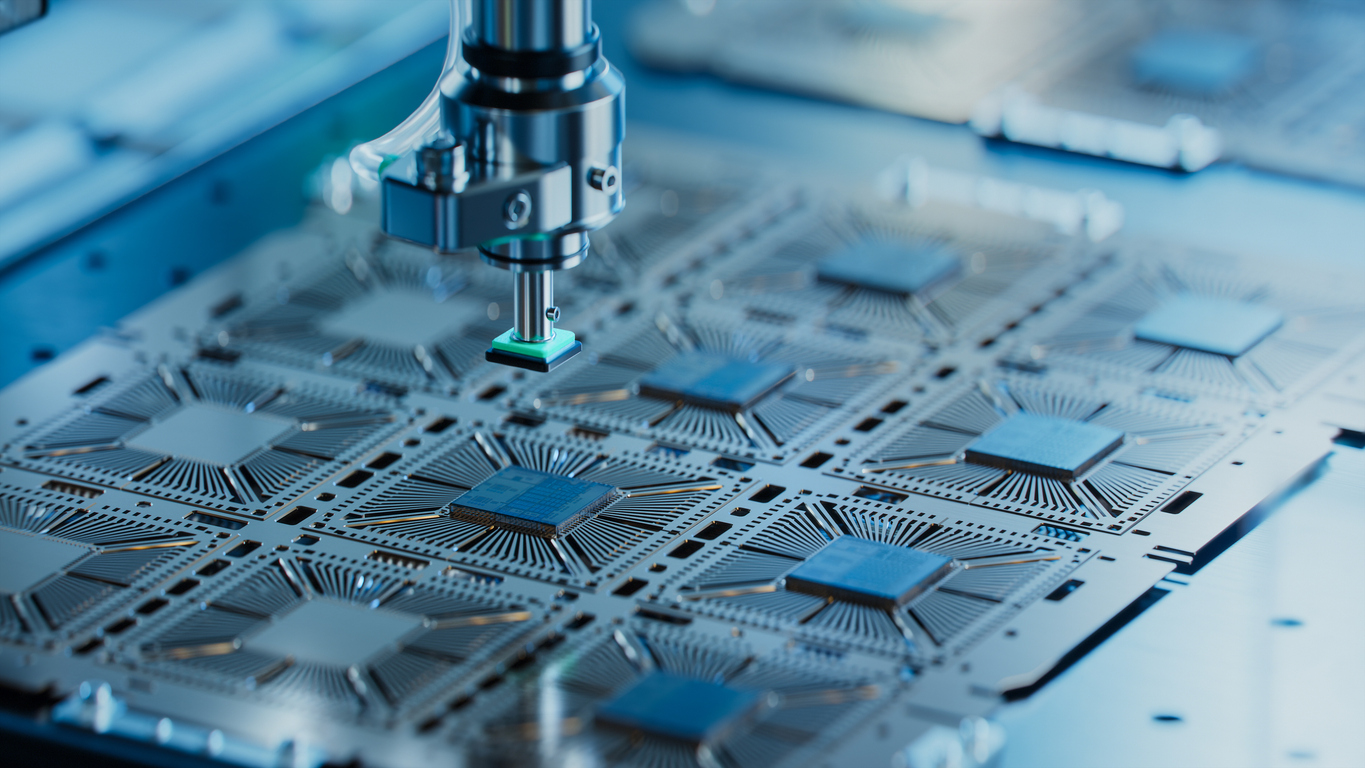

Dry ice cleaning offers a highly effective solution for the strict requirements for cleanliness and surface protection in the semiconductor industry. Especially in this sensitive area, where even the smallest impurities can lead to significant production problems, cleaning quality plays a key role.

The cleaning of semiconductor components is a crucial step in the production and maintenance of electronics. In recent years, the dry ice cleaning method has proven to be particularly effective and is setting new standards in the industry. Dry ice, which consists of frozen CO₂, has the advantage that it works without water and chemical cleaning agents, which prevents damage to sensitive components.

Dry ice cleaning represents a revolutionary solution to the challenges of semiconductor cleaning. With its high efficiency and environmental friendliness, it plays a decisive role in the production of high-quality electronics.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

One of the outstanding advantages of dry ice blasting technology is its ability to meet the highest cleanliness requirements. Semiconductor components are often complex and particularly susceptible to contamination, which can affect the functionality and reliability of the end products. Dry ice cleaning makes it possible to thoroughly clean even the finest cavities, ensuring that all residues, be it oil, grease, traces of smoke or production residues such as release agents, are removed.

Another key advantage of this cleaning technique is the gentle treatment of surfaces. While conventional cleaning methods often use abrasive materials that can damage the sensitive surfaces of electronic components, dry ice is non-intrusive. During cleaning, the dry ice sublimates directly and leaves no wet residue, reducing the risk of corrosion or other damage. This is particularly important as many of the materials used are sensitive to mechanical impact.

The use of dry ice blasting technology in the field of semiconductor technology minimizes static charges. As dry ice leaves no moisture behind during sublimation, the risk of electrostatic discharge, which could damage sensitive semiconductor components, is significantly reduced. This is particularly relevant as many semiconductor components are very sensitive to static electricity.

Another important feature of dry ice cleaning is the option of integrating special soundproofed blasting booths for manual work. These provide employees with a pleasant working environment, while at the same time effectively supporting the cleaning of individual components or complex assemblies. The flexibility of this method is also demonstrated by the adaptable nozzle guidance, which can be automated using robot modules. This technology enables precise and repeatable application, ensuring consistent cleaning quality.

Another practical advantage of dry ice cleaning is the small amount of space that the systems require. Compared to other cleaning methods, which often require extensive equipment and storage space, dry ice blasting units can be easily integrated into many production environments without significantly disrupting existing processes.

In the semiconductor industry, dry ice cleaning is particularly important for the pre-treatment of semiconductor components. The thorough removal of fingerprints, dust, fibers and other deposits before further processing ensures that the quality and functionality of the end products remain at the highest level. In an industry where reliability and precision are crucial, dry ice cleaning contributes significantly to an optimized production chain.

The cleaning of semiconductor wafers requires special care, as the sensitive wafers can easily be affected by dust, particles and chemical residues. Dry ice cleaning is an effective method for the gentle removal of such contaminants. In this process, the dry ice sublimates directly from solid to gas without leaving any residue on the surface. This technology is particularly effective against dust particles, fingerprints and chemical residues.

In semiconductor production, machines and production facilities are often faced with the challenge of removing chemical solutions, oils and other contaminants. This is where dry ice cleaning impresses with its efficiency and thoroughness. The regular removal of residues using dry ice not only extends the service life of the machines, but also ensures the quality of the end products.

Another area of application for dry ice cleaning is the removal of chemical residues that can occur during the production of semiconductor components, for example during etching or impregnation. The use of dry ice makes it possible to gently remove these residues without having to resort to aggressive chemicals or solvents. This not only helps to improve the quality of semiconductor products, but also minimizes the risk of environmental damage.

Dry ice cleaning also plays an important role in the maintenance of high-precision microscopes used in the semiconductor industry to analyze wafers and components. These microscopes require perfect cleanliness to ensure accurate measurements and inspections. Dry ice is ideal for cleaning sensitive lenses and optical components as it does not cause any scratches or other damage.

The housings of semiconductor components also need to be cleaned. Thanks to dry ice cleaning, this can be done efficiently without the need for disassembly. This saves both time and resources.

Dry ice cleaning is a powerful technology that meets the specific requirements of the semiconductor industry. Its advantages – from meeting the highest cleanliness standards and gentle surface treatment to the possibility of automation and space savings – make it an indispensable tool in modern manufacturing. The use of this technology not only improves the quality of products, but also increases the efficiency of production processes, positioning dry ice cleaning as a pioneering solution in the semiconductor industry.

You can reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information