The world of dry ice cleaning has developed considerably in recent years. White Lion is a manufacturer of dry ice cleaning machines. We sell machines that not only work effectively, but are also compact and mobile, making them ideal for a wide range of applications. Our high-quality “Made in Germany” dry ice cleaning machines can be used in various sectors, such as industry, the automotive sector and medicine.

The selection of these dry ice cleaning machines is large, and there are many different models and prices to choose from. Some models are specifically designed for use in cars, while others are suitable for a wider range of applications. It is important to consider the specific requirements and area of application, as well as the user’s available budget and preferences, to make the best choice.

The advantages of a dry ice cleaning machine are its compactness and mobility. It is easy to transport and can be used in different locations without the need for special infrastructure. This makes it an ideal solution for professional cleaners who can offer their services quickly and efficiently.

In addition to our systems, we offer an extensive range of accessories and spare parts. Depending on the area of application, we can provide you with the right set for your challenge. We will provide you with comprehensive advice and offer you the best solution for your task.

Dry ice cleaning is an innovative and environmentally friendly method for cleaning machines and production facilities. This process uses frozen CO2 in the form of pellets, which are accelerated to high speeds by compressed air and hit the surface in a jet to remove contamination. Only the dirt to be removed is removed without damaging the surface to be cleaned.

The advantages of dry ice cleaning are manifold. The dry ice blasting process can be used without having to stop and dismantle machines, which minimizes machine downtime. Being able to carry out the cleaning process during production makes this cleaning method not only effective but also cost-efficient. In addition, the machines and systems are quickly ready for use again after cleaning, as the process works without water and they do not need to be dried. The non-abrasive

Cleaning with dry ice can be used in a wide range of industries and areas, for example the automotive industry, mechanical engineering, electrical industry, food production, chemical and pharmaceutical industry, plastics and paper industry and many more. Materials such as metals, plastics, wood, glass and textiles can be cleaned particularly effectively. The use of CO2 ice pellets as a blasting medium is also particularly suitable for live elements and hard-to-reach areas.

You can reach us during our office hours (08:00 to 16:00) by telephone on 0 61 51 / 60 66 82 0

100% availability is our service concept and high availability and reliability of your dry ice blasting system is the result.

Dry ice blasting has established itself in the automotive industry as an effective and environmentally friendly cleaning method for car bodies, engines and other components and has become indispensable in this sector. This technology uses frozen carbon dioxide (CO2) to remove paint, grease, oil, soot and deposits. The thermal shock caused by the vaporization of the dry ice loosens the contaminants from the surface without causing any damage. This enables gentle cleaning that improves aesthetics and functionality.

Modern cars are created using a variety of manufacturing processes in which dry ice blasting has become standard. The areas of application for dry ice blasting in this industry are diverse. In addition to cleaning car bodies and engines, it is used to prepare surfaces for painting and to remove paint mist in paint booths or rust from wheel rims.

The advantages lie in the effectiveness, versatility and improvement of aesthetic aspects for various vehicle types. Overall, dry ice blasting offers an innovative solution for vehicle cleaning with a sustainable alternative to conventional methods.

The decision whether to buy dry ice or make it yourself depends on various factors such as cost, time, availability of raw materials and personal resources. It all depends on your individual needs and circumstances. If you need dry ice regularly, the production costs are acceptable and you have access to the necessary materials, self-production can be a good option. On the other hand, buying ready-made dry ice is more practical if you don’t have enough time or resources to make it yourself.

The quality of the dry ice is crucial for the effectiveness of dry ice blasting. Freshly produced dry ice cleans faster and more effectively than older dry ice. Over time, old dry ice loses density, which leads to a lower cleaning performance. As a result, more dry ice is required to clean a given area. In addition, the dry ice sublimates continuously, reducing the amount available over time.

In summary, the dry ice cleaning machine is a modern and environmentally friendly solution for cleaning surfaces. It offers an effective and fast cleaning method without the need for costly disposal of abrasives such as water or sand, and thanks to the advanced technology and numerous application possibilities of the compact systems, our customers can be sure that we will find the right solution for their cleaning needs.

We at White Lion will be happy to advise you in detail and provide you with technical information on our dry ice blasting machines. We are your competent contact and supplier when it comes to sales and offers for cleaning machines for this process. We offer you a wide range of options with different models and prices and help you to make the best choice with the right system for your specific requirements.

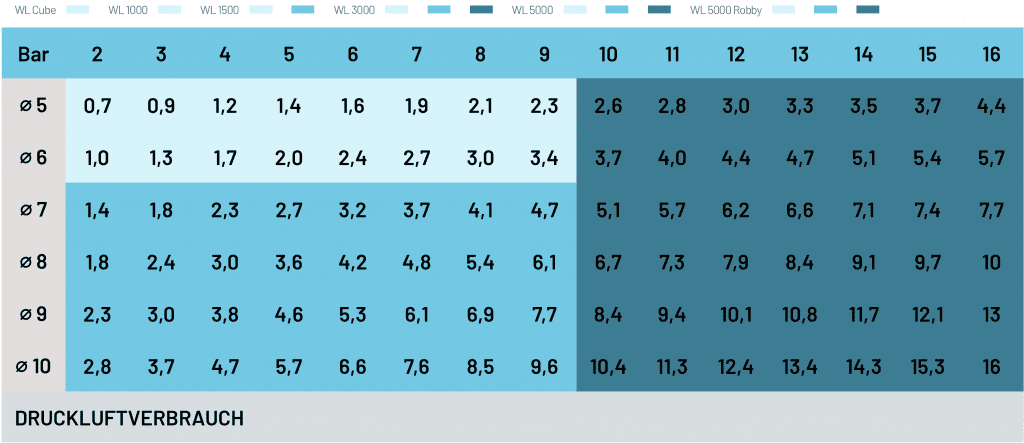

| Bar | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| ⌀ 5 | 0,7 | 0,9 | 1,2 | 1,4 | 1,6 | 1,9 | 2,1 | 2,3 | 2,6 | 2,8 | 3,0 | 3,3 | 3,5 | 3,7 | 4,4 |

| ⌀ 6 | 1,0 | 1,3 | 1,7 | 2,0 | 2,4 | 2,7 | 3,0 | 3,4 | 3,7 | 4,0 | 4,4 | 4,7 | 5,1 | 5,4 | 5,7 |

| ⌀ 7 | 1,4 | 1,8 | 2,3 | 2,7 | 3,2 | 3,7 | 4,1 | 4,7 | 5,1 | 5,7 | 6,2 | 6,6 | 7,1 | 7,4 | 7,7 |

| ⌀ 8 | 1,8 | 2,4 | 3,0 | 3,6 | 4,2 | 4,8 | 5,4 | 6,1 | 6,7 | 7,3 | 7,9 | 8,4 | 9,1 | 9,7 | 10 |

| ⌀ 9 | 2,3 | 3,0 | 3,8 | 4,6 | 5,3 | 6,1 | 6,9 | 7,7 | 8,4 | 9,4 | 10,1 | 10,8 | 11,7 | 12,1 | 13 |

| ⌀ 10 | 2,8 | 3,7 | 4,7 | 5,7 | 6,6 | 7,6 | 8,5 | 9,6 | 10,4 | 11,3 | 12,4 | 13,4 | 14,3 | 15,3 | 16 |

| DRUCKLUFTVERBRAUCH | |||||||||||||||

Compressed air consumption in m3/min. – Pressure data in bar – ⌀ = nozzle diameter 0.5 m3 (0.7 + 0.5 = 1.2 m3)

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information