Dry ice blasting in foundries

A dry ice blasting machine is an enrichment for metal foundries in various ways. Among the possible applications the cleaning of casting tools is certainly the greatest challenge. With the dry ice blasting system you can remove separating agents from casting mould twice as fast as with conventional methods. The downtime ist drastically reduced.

Not only casting tools but also workpieces can be finished wir the dry ice blasting process. Resin residues as found in zinc die casting can be eliminated completely with a dry ice blasting machine. Scalings are also not a problem for the equipment from White Lion.

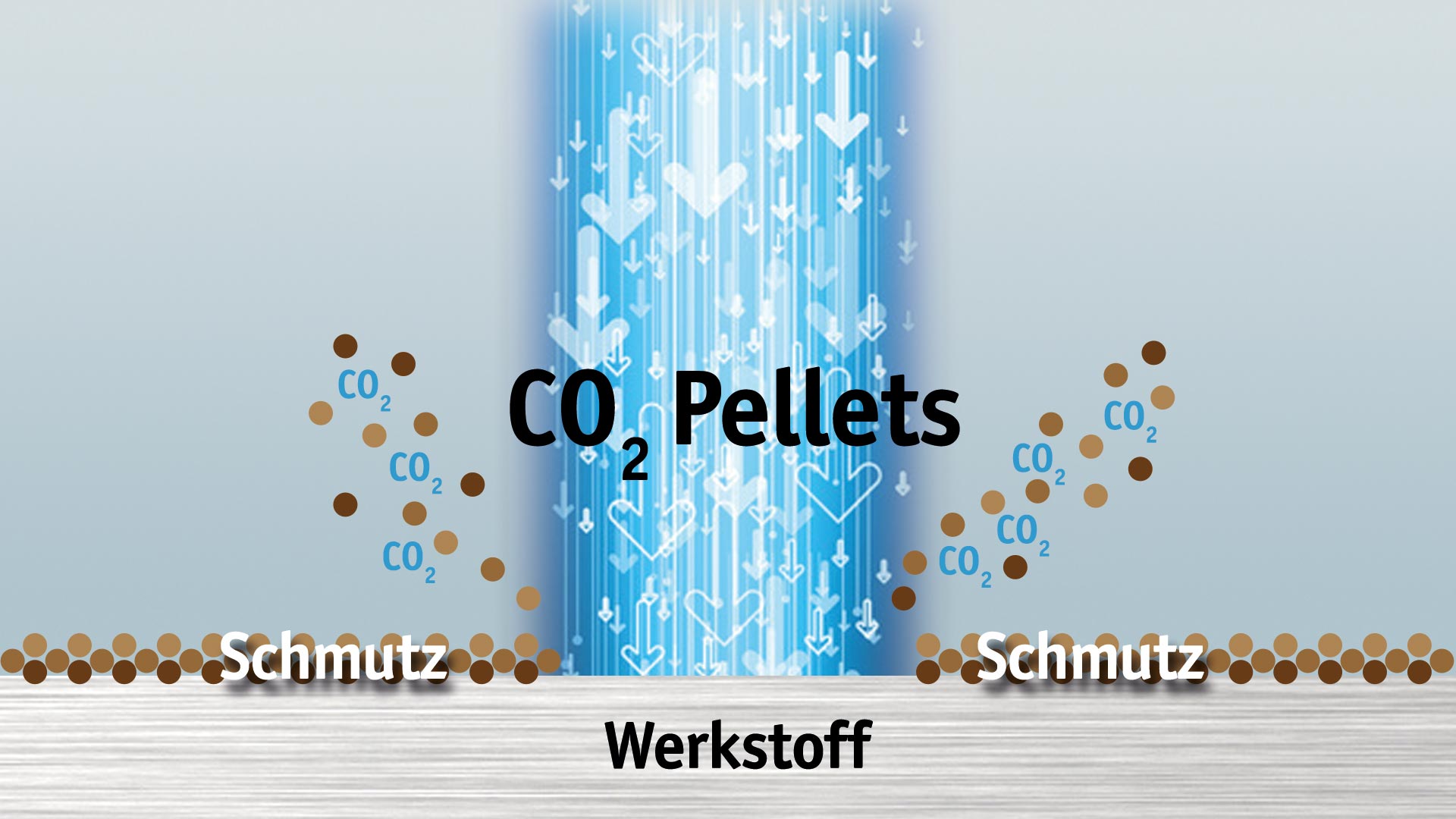

The reason for the high efficiency of the dry ice blasting process is its special functionality: A dry ice blasting machine (for example the White Lion WL 3000 Profi) blends compressed air with dry ice pellets and accelerates them thereby to almost 300 m/s. When impacting the workpiece the contamination is exposed to a selective cold shock. Due to the different thermal expansion coefficients of contamination and workpiece on the one hand and the force of impact and sublimation on the other hand, the dirt completely detaches from the workpiece. This leaves a clean and undamaged surface.

After the impact, the dry ice passes directly into the gaseous state, there are no residual abrasive residues which must be disposed of in an expensive manner. Only the chipped dirt must be removed. This process is thus not only dry and surface-friendly, but also more environmentally friendly than conventional processes.

This is especially interesting for foundry factories: The White Lion dry ice blasting machine WL 1000 MiniMax comes as standard without a chassis in a stationary version. If desired, this device can be calibrated for its intended purpose and set up in such a way that it can no longer be adjusted by accident.

White Lion also offers customised automation solutions that allow the cleaning of casting tools by controlling a robot. This means that White Lion blasting systems can also be integrated into highly automated production processes without problems. The WL 5000 Robby model speaks all common robot languages and in the special version WL 5000 Robby Plus, a pelletizer is also installed for the production of dry ice pellets.

Let us advise you on the optimum use of dry ice blasting technology. We will be happy to help you!