Ice blasters are innovative devices that use dry ice to effectively clean surfaces. As a leading manufacturer and supplier, White Lion offers the opportunity to purchase or rent such a device and benefit from its numerous advantages.

The dry ice blasting machines prove to be an efficient and environmentally friendly method of surface cleaning. They use dry ice, which is produced at extremely low temperatures of -79°C from liquid carbon dioxide. Dry ice is characterized by its high strength of 2 Mohs, comparable to plaster or chalk, and its low weight. The dry ice pellets are accelerated using compressed air and directed at the surface to be cleaned. The dry ice p ellets hit the surface at high speed and the difference in temperature causes shock cooling, dissolving dirt, grease and bacteria in just a few minutes to clean the surface. Compared to conventional cleaning methods, such as sandblasting, dry ice blasting machines offer many advantages. They do not require any additional cleaning agents, as the blasting agent of solid carbon dioxide alone is extremely effective and therefore leaves no chemical residue behind. They are also environmentally friendly as they leave no harmful residues or vapors and the pellets go directly into a gaseous state, which makes disposal easier.

It may be more economical to produce your own blasting agent if you regularly need larger quantities. If you only need the abrasive occasionally or don’t have space for the equipment, it makes more sense to purchase the dry ice via deliveries. Ultimately, it depends on your individual requirements and circumstances as to whether it is worth producing it yourself or having it delivered. You are welcome to ask us about this and we will work with you to determine the best option for your company.

Ice blasters are particularly suitable for sensitive areas, as they do not release any moisture and therefore prevent the formation of mold or rust. The areas of application for dry ice cleaning are diverse, from the automotive industry and food production to construction and the electronics industry. They are particularly useful for cleaning hard-to-reach areas such as machines, motors, pipelines or electrical systems. Thanks to their high cleaning efficiency and time savings, they are also an economically viable solution. Dry ice blasting is the ideal choice for companies looking for a quick cleaning solution without chemical substances, setting an effective and environmentally friendly standard for cleaning in various industries.

Various industries use this blasting process. In the automotive industry, it is used to thoroughly remove dirt, oil and grease residues from engines, gearboxes, body parts and wheel rims. This process is also ideal for the underbody of classic cars, vintage cars and vehicles of all kinds in general. Deposits are removed thoroughly and gently and ice blasting provides an excellent basis for new underbody protection. This method protects sensitive parts from damage and ensures efficient cleaning.

Dry ice cleaning is used in food production to remove sticky residues, grease, oil and other soiling from production facilities, conveyor belts, cooling systems and other surfaces. The use of dry ice leaves no harmful residues and ensures hygienically clean production conditions.

Dry ice blasting is also used in the construction industry to remove paint, graffiti, dirt and other impurities from bricks, facades, concrete surfaces and other structures. This method enables quick and effective cleaning without the use of water or chemicals.

In the electronics industry, dry ice blasting machines are used to remove dust, grease, oil and other contaminants from sensitive electrical appliances, control panels, housings and cables. Ice blasting prevents damage to electronic components and ensures thorough and easy cleaning without causing electrical faults.

In shipbuilding, this process is used to remove rust, dirt, tar and other soiling from ships, tanks, bulkheads, engine rooms and other surfaces. This method offers an efficient way of removing soiling and extending the service life of ships.

The versatility and effectiveness of ice blasting can be seen in various industries where a thorough and gentle cleaning method is required.

You can reach us during our office hours (08:00 to 16:00) by telephone on 0 61 51 / 60 66 82 0

100% availability is our service concept and high availability and reliability of your dry ice blasting system is the result.

Ice blasting is proving to be extremely popular with customers and users due to its efficiency, versatility and environmental friendliness. With a dry ice blasting machine from White Lion, customers have the opportunity to clean surfaces quickly and thoroughly and benefit from technological advances.

White Lion, an experienced manufacturer and supplier of dry ice blasting machines, is always available to its customers for inquiries and consultations. The team of experts provides support in selecting the right device, be it for information on technical details, technical data, the operation of a blasting system, prices or special applications. We will prepare an individual offer for you.

In addition, White Lion offers a wide range of accessories and spare parts to optimize performance and efficiency. Regular maintenance and care are essential to extend the life of the machine and ensure that it is always ready for use.

If you only need the dry ice blasting machine temporarily, renting a machine is also an option. We provide you with a dry ice blasting machine for the desired period of time so that you can clean flexibly and without high investment costs.

Whether you want to buy or rent a dry ice blasting machine – contact White Lion today for more information about ice blasting and its many benefits. We look forward to your inquiry!

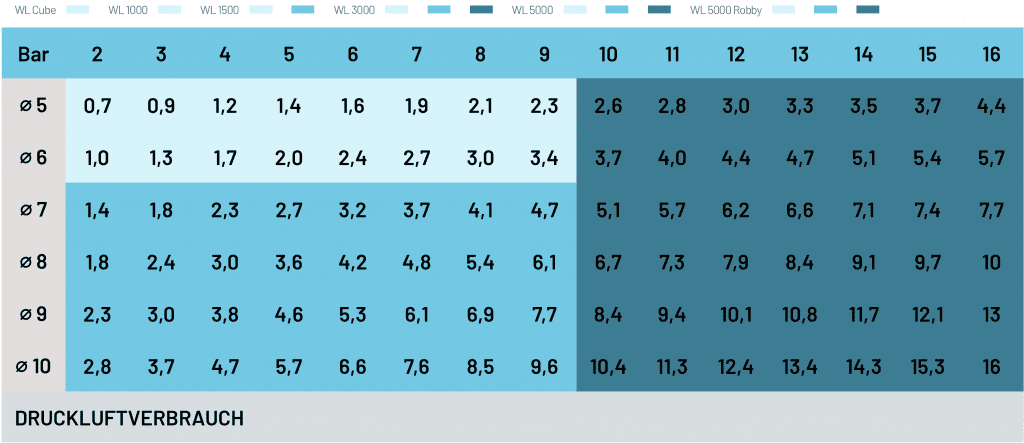

The efficiency of this blasting process depends on various factors, such as the amount of compressed air, the air pressure, the amount of dry ice pellets, the shape and size of the nozzles and the cleaning time. In particular, the amount of compressed air and the air pressure play a decisive role in the cleaning power of the system. A higher air pressure and a larger amount of compressed air enable faster and more effective cleaning with ice blasting. The combination of dry ice and compressed air dissolves and blows away dirt particles during ice blasting, ensuring thorough and rapid removal of contaminants.

The quantity of dry ice pellets is also decisive for the performance of dry ice blasting. A sufficient quantity of pellets is required to ensure an effective cleaning process. A continuous supply of ice is essential in order to carry out the cleaning process without interruptions. The shape and size of the nozzles determine the blasting angle and the intensity of the dry ice blast.

Depending on the type of surface to be cleaned and the type of soiling, different suitable nozzles can be used to achieve optimum cleaning results. The cleaning time of an ice blaster depends on the size of the surface to be cleaned and the type of soiling. As a rule, dry ice blasting machines are extremely efficient and enable time-saving cleaning compared to conventional methods. With an operating time of just a few minutes and a pressure of up to 6 bar, dry ice blasting ensures efficient and thorough cleaning in a wide range of applications.

| Bar | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| ⌀ 5 | 0,7 | 0,9 | 1,2 | 1,4 | 1,6 | 1,9 | 2,1 | 2,3 | 2,6 | 2,8 | 3,0 | 3,3 | 3,5 | 3,7 | 4,4 |

| ⌀ 6 | 1,0 | 1,3 | 1,7 | 2,0 | 2,4 | 2,7 | 3,0 | 3,4 | 3,7 | 4,0 | 4,4 | 4,7 | 5,1 | 5,4 | 5,7 |

| ⌀ 7 | 1,4 | 1,8 | 2,3 | 2,7 | 3,2 | 3,7 | 4,1 | 4,7 | 5,1 | 5,7 | 6,2 | 6,6 | 7,1 | 7,4 | 7,7 |

| ⌀ 8 | 1,8 | 2,4 | 3,0 | 3,6 | 4,2 | 4,8 | 5,4 | 6,1 | 6,7 | 7,3 | 7,9 | 8,4 | 9,1 | 9,7 | 10 |

| ⌀ 9 | 2,3 | 3,0 | 3,8 | 4,6 | 5,3 | 6,1 | 6,9 | 7,7 | 8,4 | 9,4 | 10,1 | 10,8 | 11,7 | 12,1 | 13 |

| ⌀ 10 | 2,8 | 3,7 | 4,7 | 5,7 | 6,6 | 7,6 | 8,5 | 9,6 | 10,4 | 11,3 | 12,4 | 13,4 | 14,3 | 15,3 | 16 |

| DRUCKLUFTVERBRAUCH | |||||||||||||||

Compressed air consumption in m3/min. – Pressure data in bar – ⌀ = nozzle diameter 0.5 m3 (0.7 + 0.5 = 1.2 m3)

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information