White Lion | Dry ice blasting machine | Dry ice cleaning | Areas of application | Clean chains

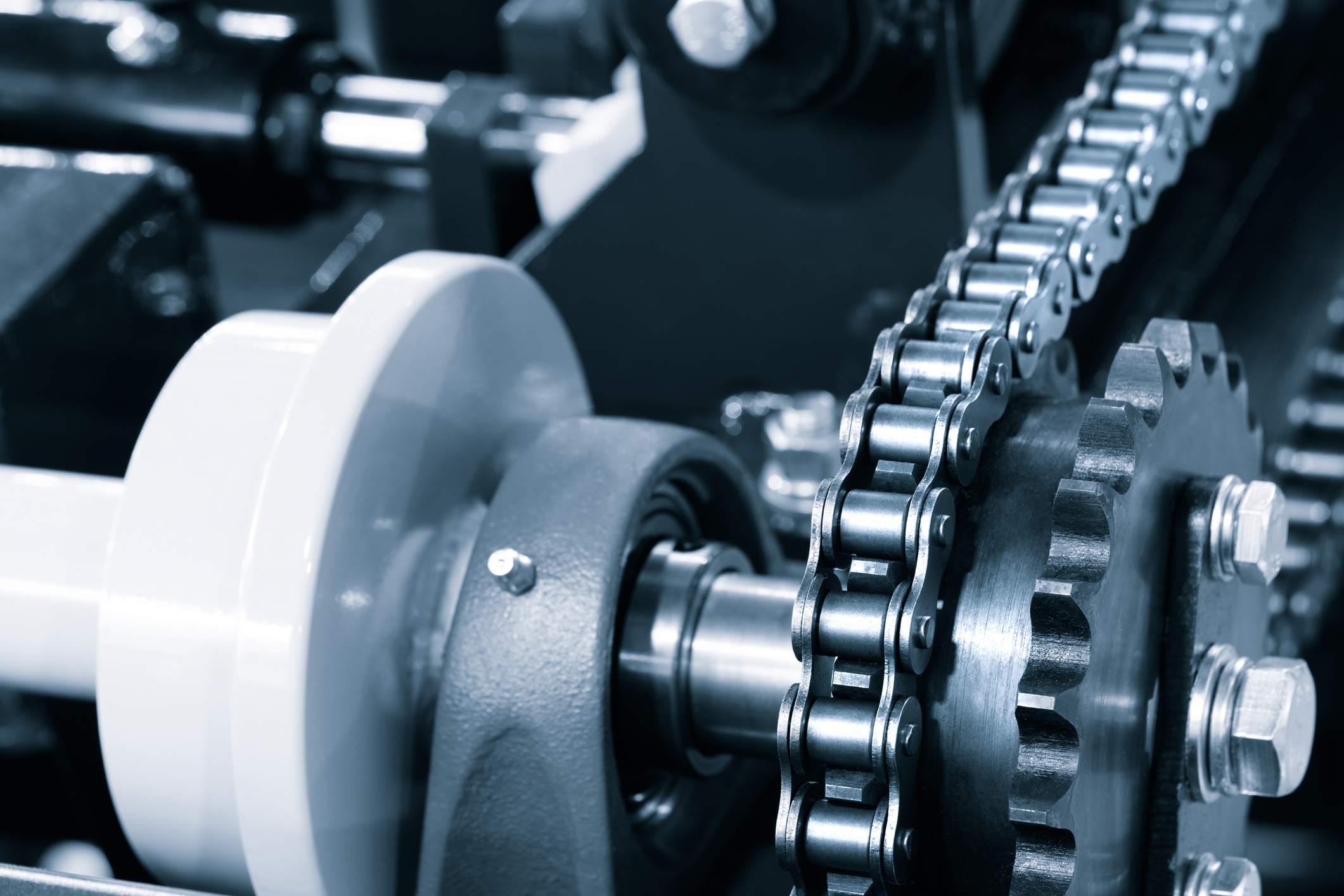

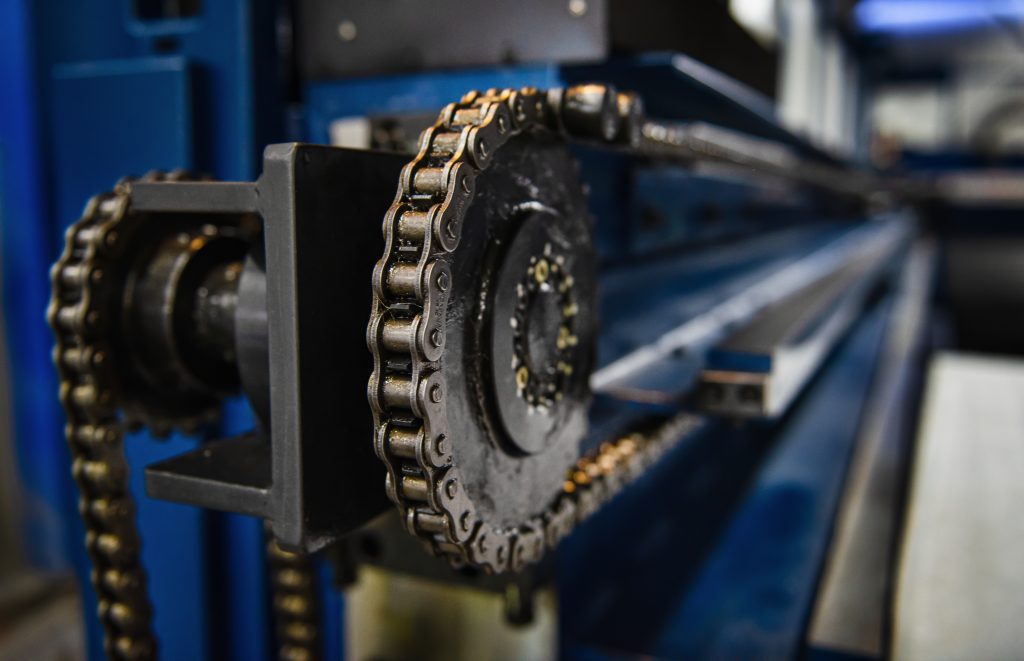

Dry ice cleaning is ideal for the thorough cleaning of chains in various industries, such as food production and the automotive industry, as it removes impurities without damaging the chains.

The application of dry ice cleaning extends across numerous industries, including food production and the automotive industry.

In the food and beverage industry, cleanliness plays a crucial role in ensuring the quality and safety of products. These production lines often use chains that are contaminated with grease, oil and other residues. Dry ice cleaning proves to be particularly effective here, as it thoroughly removes these contaminants without damaging the chains or leaving chemical residues. Given the strict hygiene regulations that apply in this industry, it is essential that such cleaning processes not only ensure cleanliness, but also contribute to compliance with food standards.

In the automotive industry, chains are indispensable in various production facilities and require regular and thorough cleaning in order to extend the service life of the machines and reduce operating costs. By using dry ice, dirt, old lubricant and other deposits can be effectively removed without the use of water or aggressive chemicals. This leads to improved machine efficiency, reduces downtime and increases productivity throughout the production process.

Mechanical and plant engineering attaches great importance to ensuring the functionality of all components. Chains must be kept in optimum condition to ensure smooth operation. Dry ice cleaning offers a precise and gentle solution that can be tailored to the specific needs of different machines. This method minimizes the risk of damage and at the same time helps to increase the service life of components, which is of crucial importance in mechanical and plant engineering.

In the wood and paper industry, machines are often exposed to extreme conditions, resulting in heavy soiling from resins and grease. Dry ice cleaning is an effective solution here too. It removes even stubborn deposits without damaging the surfaces of the machines. In addition, the use of dry ice minimizes maintenance costs and optimizes production, as the machines need to be taken out of operation less frequently. This technology therefore makes an efficient contribution to cleanliness and productivity in various branches of industry.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

Cleaning chains with dry ice has many advantages, such as thorough and gentle cleaning, environmentally friendly properties, high efficiency and great flexibility. In view of the growing importance of sustainability and efficiency, dry ice cleaning is a future-oriented option. It helps companies to improve their production processes and reduce their ecological footprint at the same time.

Dry ice cleaning is extremely gentle and minimizes the risk of damage to the chains. In contrast to mechanical cleaning methods, which can cause abrasion, dry ice acts directly on the contaminants and leaves the chains in perfect condition.

The versatility of this cleaning method allows it to be adapted to different types of chains and industries. Whether in food production, mechanical engineering or other sectors, dry ice cleaning can be tailored to specific requirements, facilitating its use in different applications.

You can reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information