White Lion | Dry ice blasting machine | Dry ice cleaning | Areas of application | Clean thread

Cleaning threads with dry ice has established itself as a particularly effective method for removing a variety of contaminants that frequently occur in industrial applications.

Dry ice cleaning offers many advantages that make it the preferred choice for thread cleaning. As the dry ice sublimates during the cleaning process and turns into gas, it leaves no residue on the surface. This means that the threads are ready for use again immediately after cleaning.

Another plus point is the thorough and efficient cleaning, even in hard-to-reach areas. The dry ice gets into the smallest gaps and crevices and removes impurities that are often difficult to remove using conventional cleaning methods. In addition, the dry ice cleaning process is non-abrasive, which preserves the integrity of the threads and the structure of the material.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

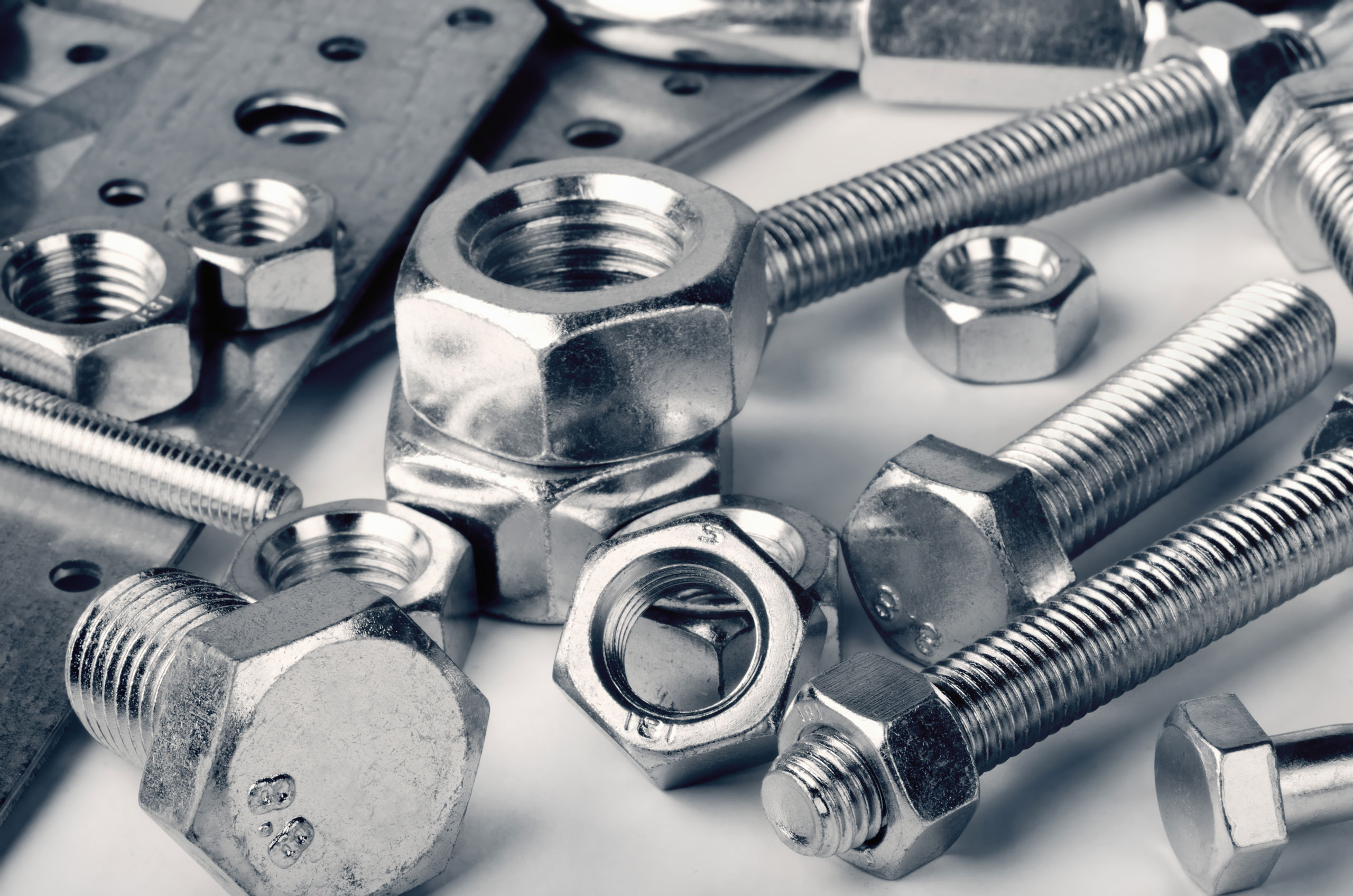

In practice, threads are exposed to various types of soiling that can significantly impair their functionality. Several factors play a role here.

First of all, oil and grease residues are a common problem, especially in the mechanical engineering and automotive industries. Lubricants are essential to ensure the smooth operation of moving parts. Over time, however, these oils and greases build up on the threads and form films that make it difficult to screw in or replace screws and bolts correctly. Regular removal of this residue is therefore crucial to prevent malfunctions.

Another common problem is paint and varnish residue that can penetrate the threads during many manufacturing processes, such as painting or coating. Such residues often block the threads and impair the accuracy of fit, which can ultimately reduce the stability of the connections.

In addition, threads that are not sufficiently protected from moisture can develop rust. Corrosion not only leads to changes in the shape of the thread, but also significantly impairs the strength and load-bearing capacity. Regular cleaning and maintenance are therefore essential to extend the service life of the components.

In industrial environments, machines and their components are also often exposed to dust and dirt. These particles can accumulate in the threads and impair their functionality, which can lead to considerable difficulties, particularly when assembling and disassembling components.

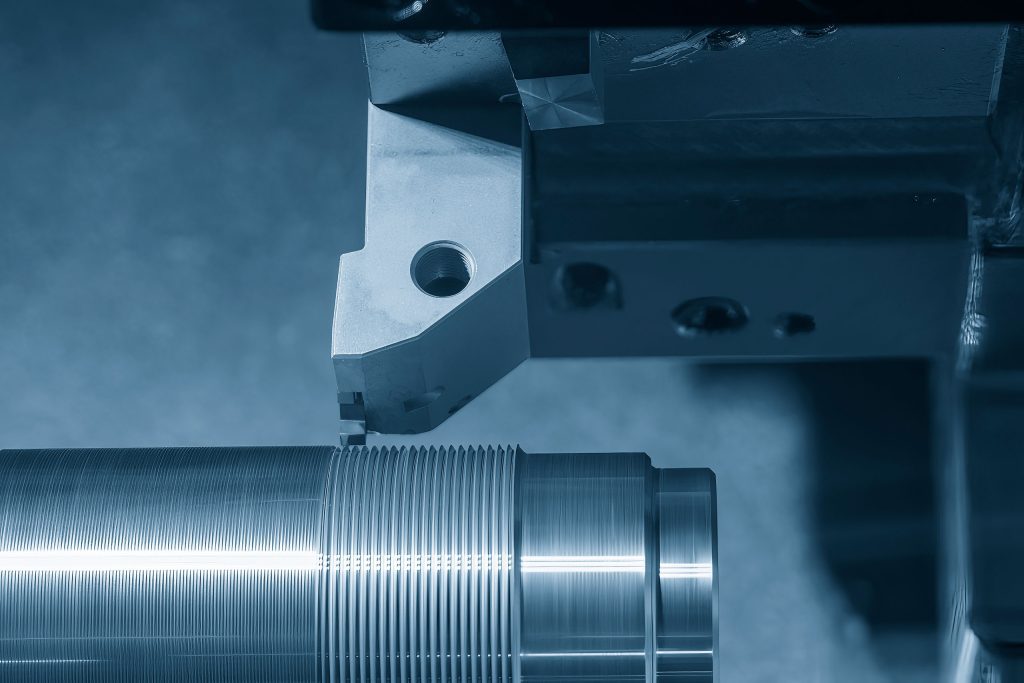

After all, when threads are machined, for example during turning or milling, metal chips or other impurities often accumulate in the threads. These residues must also be removed to ensure a clean and secure connection.

The regular use of dry ice cleaning can not only significantly increase the service life and performance of components, but also reduce the total cost of ownership in industrial production through less downtime and less cleaning effort. Companies that rely on dry ice cleaning benefit from higher efficiency and quality of their products.

It is therefore very important to clean and maintain threads regularly to ensure their optimum functionality and service life.

You can reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information