White Lion | Dry ice blasting machine | Branches & Industries | Pharmaceutical industry

Cleanliness and hygiene play a central role in the pharmaceutical industry. The strict requirements for production conditions demand highly effective cleaning methods. In this context, dry ice cleaning is becoming increasingly important. This innovative cleaning method offers numerous advantages that make it the ideal choice for the pharmaceutical industry.

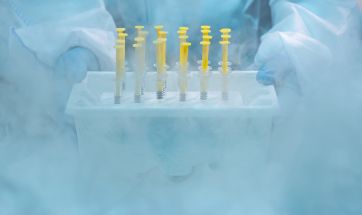

In today’s pharmaceutical industry, both dry ice cleaning and the use of dry ice for cooling are indispensable processes that make a decisive contribution to efficiency and safety in production and logistics. These technologies are characterized not only by their high performance, but also by their environmental friendliness, which makes them preferred solutions in an increasingly sustainable business environment.

Dry ice cleaning is a particularly effective method for removing dirt and deposits from sensitive surfaces. Instead of using aggressive chemicals or water, which

As this method could damage materials or leave residues, it uses frozen carbon dioxide, which sublimates on contact with dirt and gently dissolves it. This innovative technique not only minimizes the risk of damage, but also significantly reduces cleaning times, which is invaluable in the fast-paced pharmaceutical world.

Dry ice also plays a crucial role in the cold chain of pharmaceutical products. Many medicines and vaccines require strict temperature controls to guarantee their efficacy. Dry ice provides a reliable and effective solution by ensuring a constant, deep-frozen environment. This ability to maintain critical temperature conditions is particularly important in the storage and transportation of biological materials and sensitive pharmaceutical formulations.

The versatility of dry ice and the continuous technological advances in the field make it an indispensable tool for success in pharmaceutical production and logistics. Combining efficiency, environmental sustainability and safety aspects, dry ice is not only a cost-effective choice, but also helps to maintain quality standards that are essential for patient safety. In the future, the importance of these processes in the pharmaceutical industry is expected to continue to grow as companies strive to optimize their processes while incorporating environmentally conscious practices.

Would you like to find out more about us,

request a non-binding quote or

have questions about our dry ice blasting machines?

Dry ice cleaning offers the pharmaceutical industry numerous advantages that make it a preferred cleaning method. An outstanding feature of this technology is its environmental friendliness, as it does not require the use of chemical cleaning agents. As a result, no harmful waste is produced and the method leaves virtually no residue, making it a sustainable alternative to traditional cleaning methods.

Another decisive advantage of dry ice cleaning is its efficiency and the associated time savings. The cleaning process is fast and automated, which significantly reduces machine downtime. In an industry where time and efficiency are of the utmost importance, this is a key factor.

In addition, dry ice cleaning is particularly gentle on sensitive materials. While mechanical cleaning methods often entail the risk of damage, the gentle effect of dry ice allows equipment and surfaces to be handled with care. This is of paramount importance in the pharmaceutical industry, where precision and quality are essential.

Last but not least, dry ice cleaning helps to reduce cross-contamination. As no water-based or chemical cleaning agents are used, the risk of contaminating sensitive areas is reduced. This ensures that cleanliness and hygiene, which are top priorities in the pharmaceutical industry, are maintained in the best possible way.

Dry ice cleaning plays a crucial role in the pharmaceutical industry, where it is used in various important areas of application. One key aspect is the cleaning of production facilities. In pharmaceutical production facilities, it is essential to clean equipment regularly to minimize contamination risks and ensure product quality. This is where dry ice cleaning proves to be extremely effective, as it thoroughly removes production residues from machinery and equipment.

Another critical area is the maintenance and servicing of machines. Regular maintenance is essential to ensure a smooth production process. Thanks to dry ice cleaning, machines can be efficiently freed from accumulated deposits, which not only optimizes their performance but also extends their service life.

Dry ice cleaning is also used in the cleaning of laboratory equipment. In research laboratories, where the highest hygiene requirements apply, it offers an optimal solution for the care of sensitive equipment and instruments. This method ensures that no residues are left behind that could potentially compromise research results. Dry ice cleaning therefore makes a decisive contribution to quality assurance in the pharmaceutical industry.

Dry ice cleaning has established itself as an excellent solution to the challenges of pharmaceutical cleaning. Its efficient, sustainable and safe application makes it an ideal choice for meeting the high standards of cleanliness and hygiene in production. This makes dry ice cleaning not only a modern, but also a future-oriented solution for the challenges in the pharmaceutical industry.

You can reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information