With over 25 years of experience in the field of dry ice cleaning, we have developed over the years into one of the most innovative manufacturers of dry ice cleaning equipment. Our wide and versatile product range is not only available to our customers. We also use our products ourselves. As an industrial cleaning service provider, we can master any challenge with our high-quality machines.

You can reach us during our office hours (08:00 to 16:00) by telephone on +49 61 51 / 60 66 82 0

100% availability is our service concept and high availability and reliability of your dry ice blasting system is the result.

Dry ice cleaning machines can be used for practically all types of dirt and always guarantee a clean result without side effects. The main application of dry ice cleaning is industrial cleaning. The advantages of this process are significant. Dry ice leaves no moisture behind and there is no exposure to chemicals or aggressive cleaning agents. This fast cleaning process significantly reduces production downtime.

But this cleaning method is also clearly gaining ground in car care. The advantage is obvious, because no other device can completely clean the bodywork, engine compartment and underbody. The interior, including upholstery, can also be optimally cleaned with our compact devices. The use of dry ice is particularly powerful in the automotive sector when removing old underbody coating. The complete removal of the old underbody coating and the perfect cleaning of the entire underbody are the prerequisites for the application of long-term effective protection to the underbody. With a dry ice blasting machine, the old underbody protection and soiling are removed both gently and quickly.

Dry ice blasting has also proven to be a quick and effective solution for house renovations. Dry ice blasting can be used to effortlessly remove old layers of paint and dirt of all kinds, for example graffiti, deep-clean old roof beams, clean parquet and wooden ceilings and refresh facades so that they look like new. It doesn’t matter which surface is to be cleaned, it can be concrete, plastic, wood, ceramic or metal. This type of cleaning makes it possible to achieve results that were previously only possible with demolition and new construction.

Dry ice blasting is a versatile cleaning process with amazing results.

With dry ice cleaning equipment, you can achieve fast and lasting cleanliness without any problems. Cleaning with dry ice is an efficient yet gentle cleaning method and a quick way to remove dirt. Not only is the sensitive surface to be cleaned protected, but also the environment. Even areas that are difficult to clean can be quickly and efficiently removed from any type of dirt without leaving any residue.

Our machines are the answer to stubborn soiling and coatings that can only be cleaned efficiently with an abrasive cleaning agent. Dried paint, caked-on dust, rust or hardened machine grease can only be cleaned with great effort using conventional blasting methods. The abrasive process often irreparably damages the product to be cleaned after treatment. Dry ice is gentle on the product and hard on the dirt.

Blasting, shock freezing, embrittling, blasting off – this is the operating principle of the dry ice blasting process. Conventional blast cleaners shoot a blasting material onto the surface. This mechanically removes the adhering protection. The principle is always the same, regardless of whether it is a high-pressure water cleaner or a sandblaster. The clever and simple dry ice cleaning process has a fourfold effect on dirt.

The blasting material of the dry ice cleaner is frozen CO2 in the form of dry ice pellets. The -78 degree Celsius cold dry ice is blasted onto the surface to be cleaned at very high speed with a pressure of between 1 and 16 bar, depending on the machine. At first, the pellets act like a normal blasting medium. Anything that is particularly loosely attached is blown away. When the cold dry ice pellets hit the surface, the surface to be cleaned cools spontaneously. This results in thermal stress and the adhesion becomes brittle. The flash shock freezing causes the dirt or coating to flake off. The base material remains undamaged. The dry ice changes to a gaseous state in a flash when it hits the surface. This means that no blasting material residue remains to be disposed of. Removed dirt is simply swept up and disposed of after cleaning. Dry ice cleaning is environmentally friendly, economical and efficient.

When cleaning with dry ice, there is no health risk from toxic vapors. There is only a risk of CO2 poisoning when working in deep, unventilated rooms. Here, the CO2 collects on the floor and slowly rises. An extraction and ventilation system can ensure maximum safety. Our team will be happy to advise you on how to use the dry ice blasting process with maximum safety.

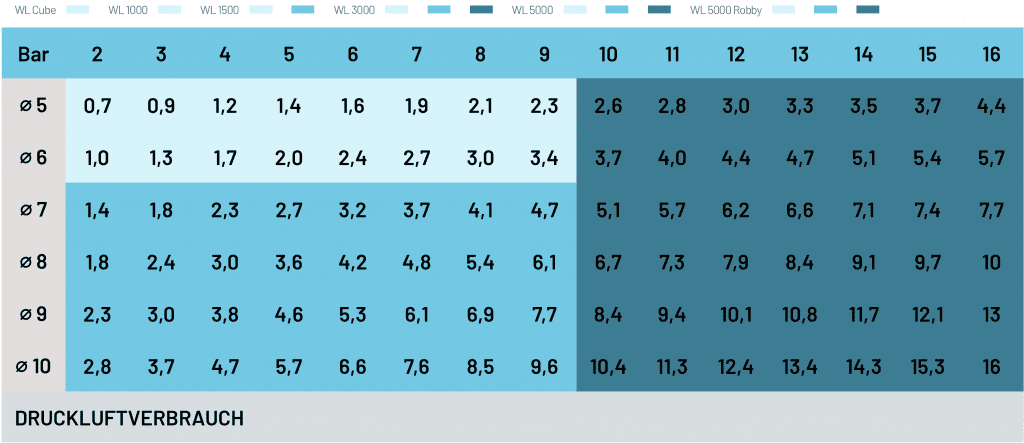

| Bar | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| ⌀ 5 | 0,7 | 0,9 | 1,2 | 1,4 | 1,6 | 1,9 | 2,1 | 2,3 | 2,6 | 2,8 | 3,0 | 3,3 | 3,5 | 3,7 | 4,4 |

| ⌀ 6 | 1,0 | 1,3 | 1,7 | 2,0 | 2,4 | 2,7 | 3,0 | 3,4 | 3,7 | 4,0 | 4,4 | 4,7 | 5,1 | 5,4 | 5,7 |

| ⌀ 7 | 1,4 | 1,8 | 2,3 | 2,7 | 3,2 | 3,7 | 4,1 | 4,7 | 5,1 | 5,7 | 6,2 | 6,6 | 7,1 | 7,4 | 7,7 |

| ⌀ 8 | 1,8 | 2,4 | 3,0 | 3,6 | 4,2 | 4,8 | 5,4 | 6,1 | 6,7 | 7,3 | 7,9 | 8,4 | 9,1 | 9,7 | 10 |

| ⌀ 9 | 2,3 | 3,0 | 3,8 | 4,6 | 5,3 | 6,1 | 6,9 | 7,7 | 8,4 | 9,4 | 10,1 | 10,8 | 11,7 | 12,1 | 13 |

| ⌀ 10 | 2,8 | 3,7 | 4,7 | 5,7 | 6,6 | 7,6 | 8,5 | 9,6 | 10,4 | 11,3 | 12,4 | 13,4 | 14,3 | 15,3 | 16 |

| DRUCKLUFTVERBRAUCH | |||||||||||||||

Compressed air consumption in m3/min. – Pressure data in bar – ⌀ = nozzle diameter 0.5 m3 (0.7 + 0.5 = 1.2 m3)

A supply of blasting material and compressed air is required to operate our blasting systems. The stronger the compressed air blast, the more efficient the dry ice cleaning process. A minimum of 10 bar compressed air is required to achieve fast and sustainable cleaning results. Powerful construction compressors are particularly efficient for this purpose. A compressor with an integrated diesel engine is particularly recommended. This reduces the load on the local power grid. It also provides the power for all the other peripherals for the dry ice cleaners.

The dry ice blasting machine is continuously filled with CO2 pellets. This is usually done manually using a small shovel. With our WL 5000 Robby Plus model, we offer a dry ice blasting system with integrated dry ice production. Dry ice production takes place directly in the appliance. Manual refilling of dry ice pellets is no longer necessary.

A White Lion dry ice cleaning device is supplied with a 5 m, 7.5 m or 10 m hose, a power cable and a nozzle set, depending on the device. Other accessories are optional.

We are your all-round contact for all aspects of the dry ice blasting process. We develop and manufacture dry ice production systems, dry ice blasting machines and high-quality thermal containers for transporting dry ice “Made in Germany” and produce dry ice with our systems. Whether you are interested in sales, rental, services or a supply of dry ice – contact us, we look forward to hearing from you!

Technical data and prices for dry ice cleaning machines, accessories, compressors and pelletizers can be obtained directly from us.

You are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More Information